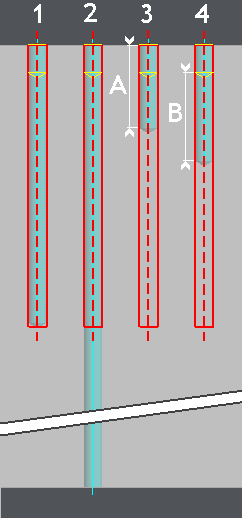

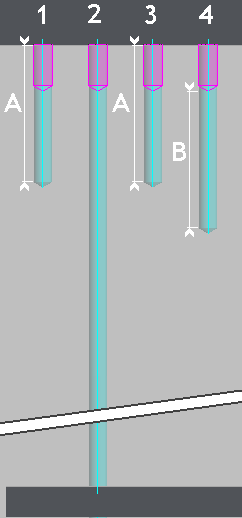

Depth - Reference and Depth

Cycle: Deep Drill & Clevis

Definition

Definition of the depth calculation according to the type of element selected.

Type of hole: the type of element selected is very important to understand the way the depth is calculated.

We can distinguish 3 types of elements:

through holes: if the hole selected is a through hole (information given during the creation of the hole), then the machining always goes through material, the depth parameters are not necessary.

blind holes: a depth is defined in the hole feature.

circles: there is no depth defined in the element. This is a special case.

4 types of depth calculation are offered:

|

|

|

|

|

|

|

|

| Blind holes | Circles |

Entity (case 1):

Stock (case 2): The machining is done through material. Manual / Entity (case 3): A value has to be entered manually in the field Depth (value A). The depth is defined according to the entity (hole or circle) Z positioning. Manual / Stock (case 4): A value has to be entered manually in the field Depth (value B). The depth is defined according to the stock value. As a prepiercing operation is defined, the depth is calculated from the bottom of the prepierced hole. |  |  |