FAQ - 3 Axis Milling

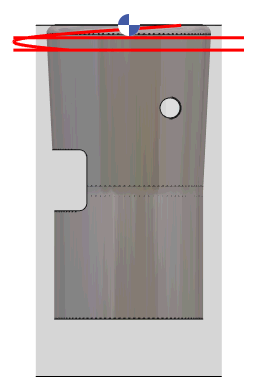

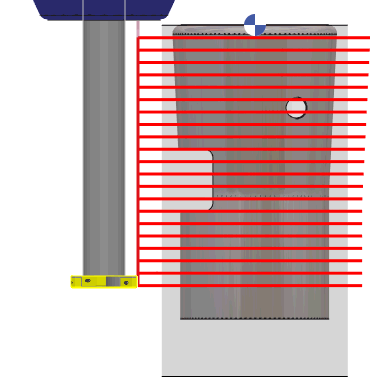

The Finishing cycle (or Z level) does not operate to the selected bottom altitude! Why? and how to fix it? |  |

The workpiece being machined has an undercut angle, and this is the reason why the machining do not go to the bottom altitude. A rough/rework operation in the same situation would go down; but the finishing and the Z level cycles are used to finish the workpiece; their algorithm is optimized, the toolpaths stay closer to the worpiece and avoid air cutting. Of course, there is one option to machine undercut areas; you can set it ON and get this result on the right. |  |

As a conclusion, if the part has an undercut shape, the finishing and Z level operations cannot machine it as a ‘cylinder’. Either you use a rough/rework operation, or you set undercut machining to Yes. Download the workpiece: Finishing.PCE | |