FAQ - 5 Axis Expert

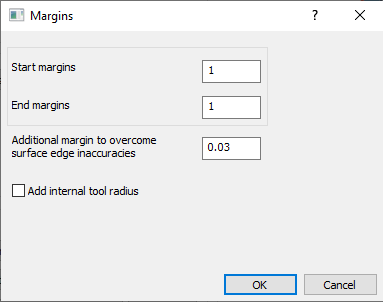

How to force tool to tilt in a only one direction? | |

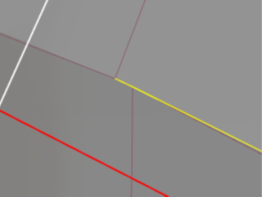

When the tool rotates unexpectedly, it is unable to identify the surface's UV curves.

|  |

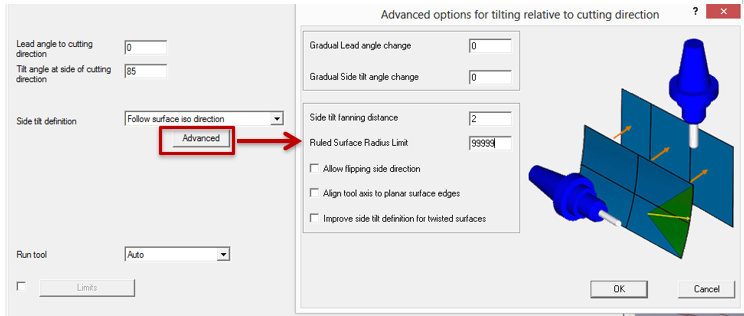

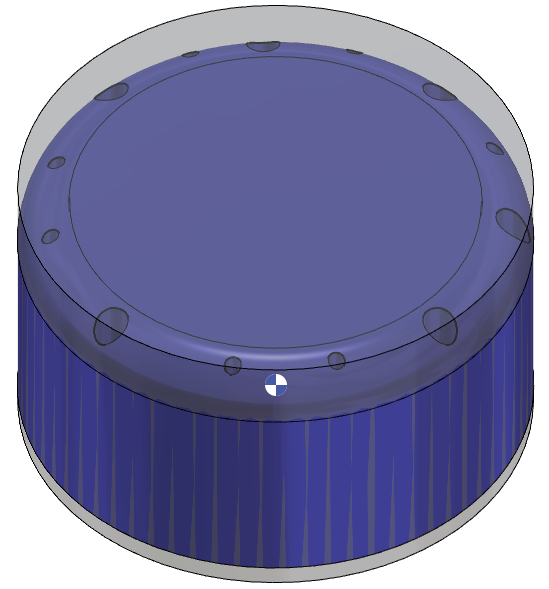

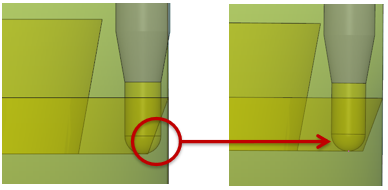

Before and After forcing tool’s direction | |

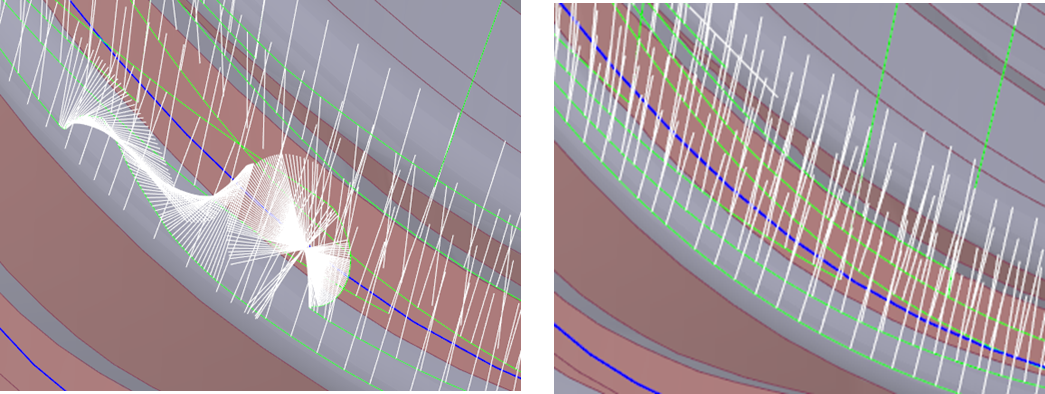

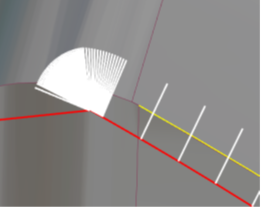

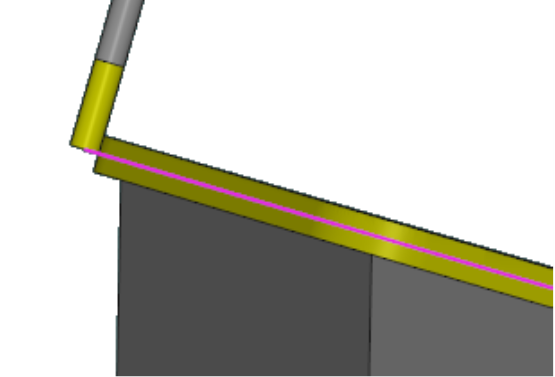

How to avoid unwanted tool vector orientation when pattern with curves are chosen ? | ||

In certain cases, selection of curves through edges may be easier. However, broken edges where the link of the interconnecting surfaces become difficult to compute, the tool motion at that point generated unwanted vectors. |  |  |

In such cases, to correct this issue it is recommended to use the face option for the curve selection. This eliminates the risk posed by broken edges and the machining toolpath and the tool vectors are generated appropriately. |  | |

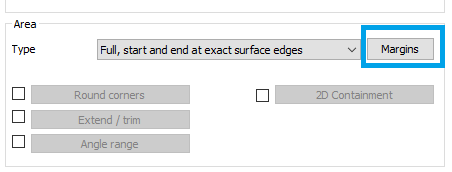

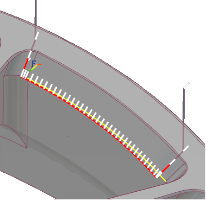

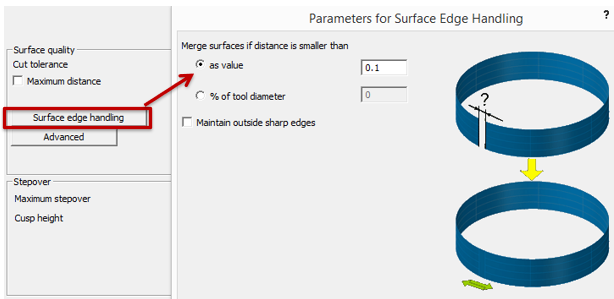

What is Surface edge handling? | ||

Surface edge handling, helps to prevent common issues such as gaps, overlaps, and unexpected behavior, ensuring a smooth and accurate machining process. Merging surfaces is an effective way to address edge accuracy issues. You can set the merge distance as a fixed value or a percentage of the tool diameter." By effectively managing surface edge handling, you can:

|  | |

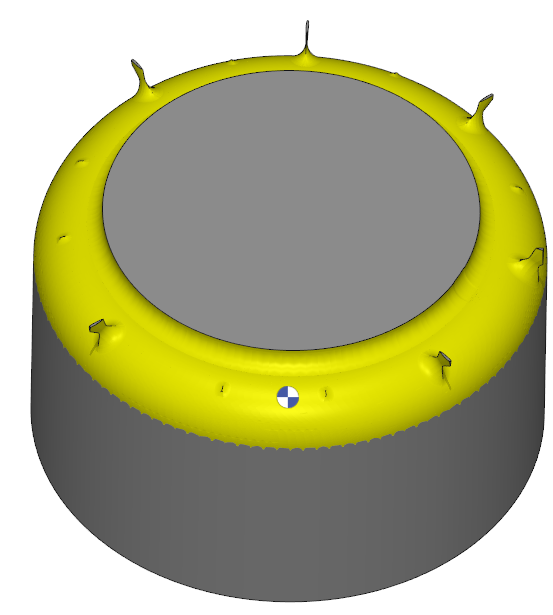

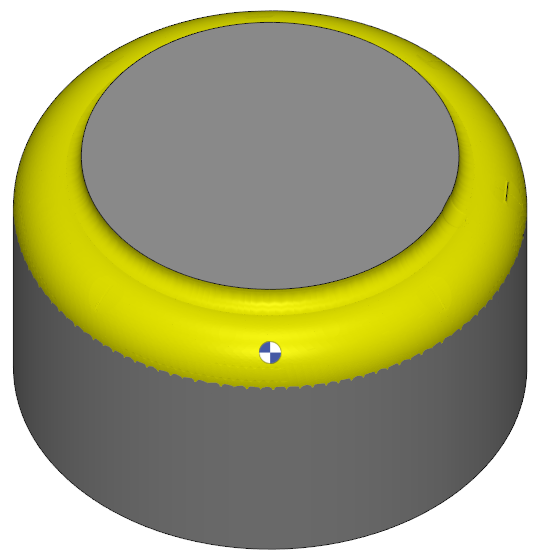

Workpiece with multiple holes |  Machined without Surface edge handling |  With Surface edge handling |

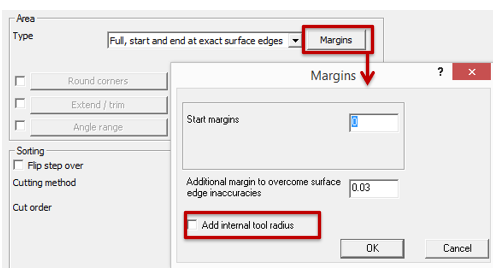

What happen when internal tool radius is activated? | |

To maintain adequate clearance in pencil trace machining, the internal tool radius must be factored into the margin for the leading curve or surface. Activating this option will add the tool radius to the specified margin, ensuring the toolpath remains tangent to the side surface with a radial offset. | |

|  |

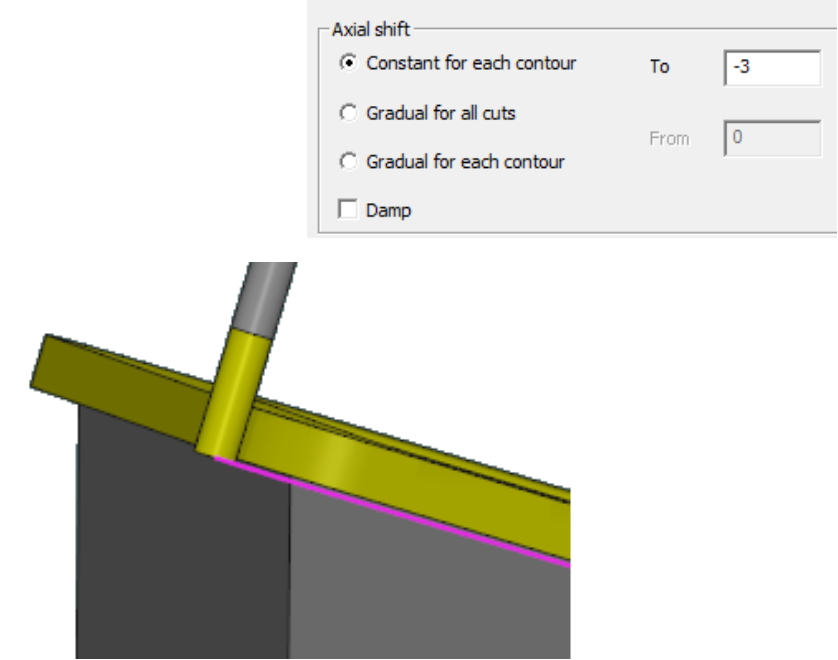

What is axial Shift? | |

Axial Shift is an offset applied to the tool along its axis. It can be used control the depth of cut and the tool’s contact point with the workpiece. The different methods for axial shift:

|  Morph between 2 curves and tilt 90° and no Axial shift |

Morph between 2 curves and tilt 90° and Axial shift set to -3mm | |