FAQ - Tooling

Can we manage Flash tools in GO2cam? | |

What we call Flash tool is the concept of multiple tools mounted on one single holder, usually, 2, 3 or 4 tools. We can manage them easily in GO2cam, by following some rules to create tools and apply machining: |  |

|  |

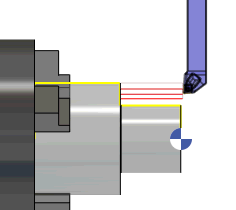

Programming of operations is done with the tool without holder. Here we program a roughing operation (insert C) and a finishing operation (insert D). |  |

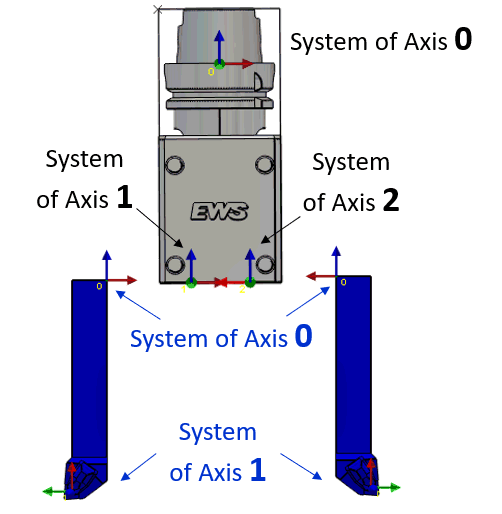

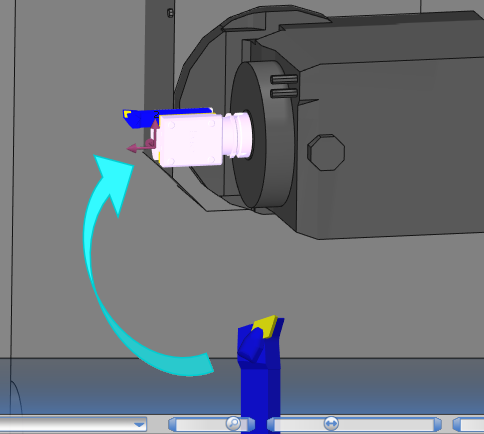

In MTE Tooling menu, the 2 tools are waiting for being mounted. With a right-click on the spindle tool support, you can choose ‘Add > a solid toolholder’. Select the flash tool. Now you can simply drag & drop the 2 tools on the 2 positions of the holder. In the machine kinematics, the spindle must be defined with a B rotation axis, to be able to index the Flash tool! |  |

Can we also manage Flash insert holder?Here, the Flash holder is an insert holder. Problem: the insert holder is part of the tool. We cannot use the same method presented above to pilot this type of tool. |  |

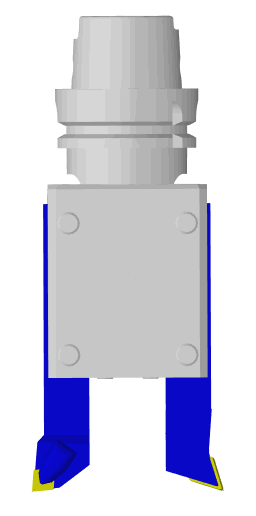

The solution is to build this insert holder as it was 2 insert holders + 1 holder:

Once the symbols are created, you can program the operations by adding insert holder + tool holder in each of the tools. In MTE tooling menu, you should break out the 2 tool holders and finally build one only tool: please watch the video to follow the complete process! You can also download holders symbols here: Double insert holder.zip |

|

Why does the system add ‘_1’ at the end of the tool name on the application of an opelist? | |

Explanation of the problem: The opelist includes the tools 'X5-Flat End Mill - D08 - R.F05' and 'X5-Flat End Mill - D08 - F.F05 that are also present in GO2cam tools library. This opelist has been created some times before or even a day before. In the mean time, there may have been some changes done to the tool in the tools library. These changes can be differences in dimension or even simply a comment for instance.

This issue in turn extends to the MTE environment and cause issues in the auto-mounting of tools with the tool numbering. | |

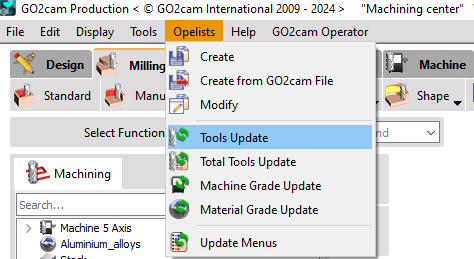

How to fix it? To prevent this situation, there is one option in the Opelist menu, called 'Tools Update'. It enables to update the tools in the opelist compared to the tools in the library.  Simply click on it, select the opelist you want to update and click on open to update it. | |