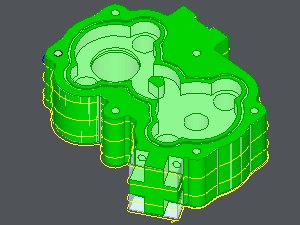

Calculation of Z Steps for Contour

Cycles: Contouring / Finish Contour / Cutting

These parameters are common for all the cycles listed above.

Z Step (Ap)

This is the Z increment between each pass. It corresponds to the cutting of the total depth. If the incremental depth is greater than the maximum depth of pass of the tool, there is a warning message.

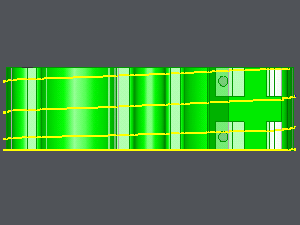

Continuous Toolpath

You can choose whether to program the plunge in continuous mode or not. This command is for the plunge to be done during the profile following or not.

Final Pass at constant Z

Definition of a contouring toolpath with an helix toolpath.

The slope angle is linked to the Z increment: the tool goes down with a Z increment value for each turn done.

You can also add one or two finishing pass with no Z motion at the end of the machining.

The parameter 'Final Pass at constant Z' is available in the following options:

| No |

| One |

| Two |

Notes:

do not define overlengths on the toolpath

do not use an approach macro on the toolpath

the profile machined has to be closed.

One final pass is done on this example.

|  |

___________________________________________________________________________________________________________________

The parameters below are specific either for Contouring or Finish Contour.

First pass with constant Z (for Contouring)

Using this parameter, you can choose to add a first pass at constant Z or not.

Constant Z Step (for Finish Contour)

| Yes: GO2cam recalculates the Z step, so that the different passes will have the same Z value. If the island altitude or the bottom altitude does not fit with the Z value, these surfaces won't be manufactured. It will remain a Z stock allowance on these surfaces. |

| No: GO2cam recalculates the Z step, so that all the surfaces will be manufactured. |