Lead in and Lead out Distances, Threads Length and End Chamfering Distance

Cycle: Threading, Die Threading, Profile Threading, Thread Whirling, Roughing of a screw, Finishing of a screw

Definition

These commands allow you to define leadin and leadout distances but also the length and an end chamfering distance for blind threads.

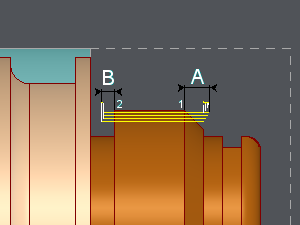

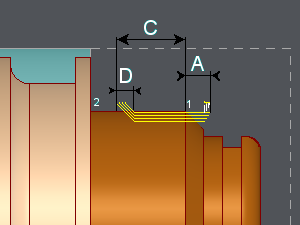

Lead in distance (A)

Lead in overlength. In general this value is the pitch multiplied by 3.

Lead out distance (B)

Lead out overlength. It can be positive or negative. In general this value is the pitch multiplied by 3.

Threads Length (C)

If this parameter is equal to 0, the thread toolpath is done on the whole last element of the profile.

If this parameter is different from 0, the thread toolpath is done with this value. The length is always given on the Z axis (even for a conical threads).

End chamfering distance (D)

It is the end chamfering distance for blind threads.

The 2 following examples show you the usings of the different parameters.

The leadout distance (B) is used in the case of threading done all along the selected profile (1 to 2).

Threads length (C) and end chamfering distance (D) are used for blind threads (profile from 1 to 2).

|  |