Machining Direction

Cycles:

All Standard cycles except: Zrepeat Pocket, Zrepeat Facing

Interpolation cycle

All Automatic Shape cycles except: PAM, Facing

Definition

Machining Direction is the choice between Down Cutting and Up Cutting.

English Terminology: Down / Up Cutting is also known as Climb / Conventional Cutting

Reminder: Down and Up Milling

Convention:

the feed is given on the workpiece

the tool rotation is clockwise (M03)

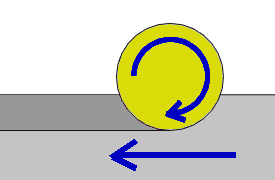

Down (Climb) Milling: tool rotation in the same direction as the feed. Comparison:

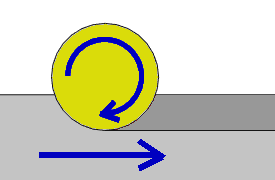

| Up (Conventional) Milling: tool rotation opposite to the feed. Comparison:

|

|  |

Forced & Optimized

Forced means that all the toolpaths will respect absolutely the machining direction.

Optimized will also respect this choice but gives to the toolpath the ability to change the direction if needed.

The 4 iterations for the machining direction are as such:

| Down cut + Forced |

| Down cut + Optimized |

| Up cut + Forced |

| Up cut + Optimized |

Special Case

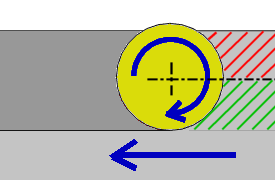

When the tool is machining in full material, or more exactly with a stepover > 50% of tool diameter, the machining is simulteanously Down AND Up!

In green the area where the tool works Down, in red the area where the tool works Up. This situation will appear in operations such as Rough/Rework and Pocket. If you set the parameter to Down/Forced for example, it cannot be fully respected when the tool is working in full material. So please do not consider that the software is doing wrong in that kind of this situation. |  |