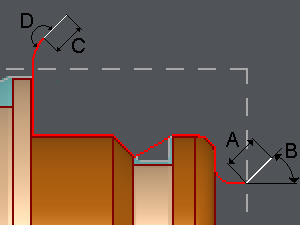

Approach and Return Angles and Distances

Cycles: Roughing, Balanced Roughing, Finish, Finish B simultaneous, Balanced Finishing, Form Finishing

Definition

These commands allow you to define approach and return rapid movements.

Approach distance (A)

It allows to input the distance defining the approach relative to the first machining element. It is inputted according to the leadin angle. If the value is zero, the entry point corresponds to the geometry point clicked with the Approach function of the SELECT panel.

If the value is not zero, the entry point is calculated from:

The extremity of the first element.

The leadin overlength.

The leadin arc radius.

Approach angle (B)

It allows to input the angle for the automatic positioning of an approach point. This angle applies itself either relative to the extremity of the first machined element, or relative to the extremity of the overlength, or relative to the extremity of the leadin arc radius.

Return distance (C)

It allows to input the distance defining the return relative to the last machining element. It is inputted according to the leadout angle. If the value is zero, the leadout point corresponds to the geometry point clicked with the Return function of the SELECT panel.

If the value is not zero, the leadout point is calculated from:

The extremity of the last element.

The leadout overlength.

The leadout arc radius.

Return angle (D)

It allows to input the angle for the automatic positioning of a return point.

This angle applies itself either relative to the extremity of the last machined element, or relative to the extremity of the overlength, or relative to the extremity of the leadout arc radius.

A. Approach distance (=10mm)

B. Approach angle (=45°)

C. Return distance (=10mm)

D. Return angle (=180°)