Curve Tolerance

Cycles: All Cycles

Definition

Maximum chordal length allowed between theoretical machining and two points of real machining on a pass. Curve tolerance has almost no influence on machining time but rather on the cycle calculation time and the NC file size.

The smaller the curve tolerance is, the more points there is to create the same toolpath. Consequently, the calculation time and the machining file are longer but the machined length is the same and the machining is more precise.

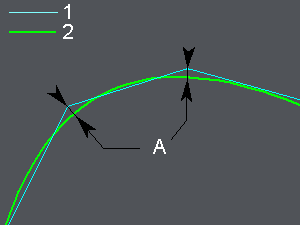

1: profile of theoretical solid or surface triangulated by GO2cam

2: profile to machine

A: 1/2 curve tolerance