About Templates and Tools - Opelists

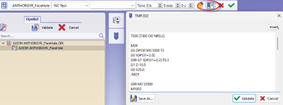

Change / Create Tool

1 - Create tool inside library

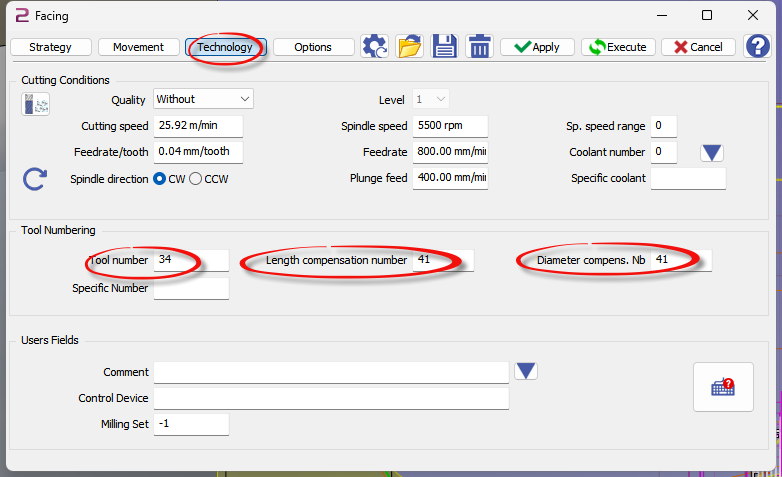

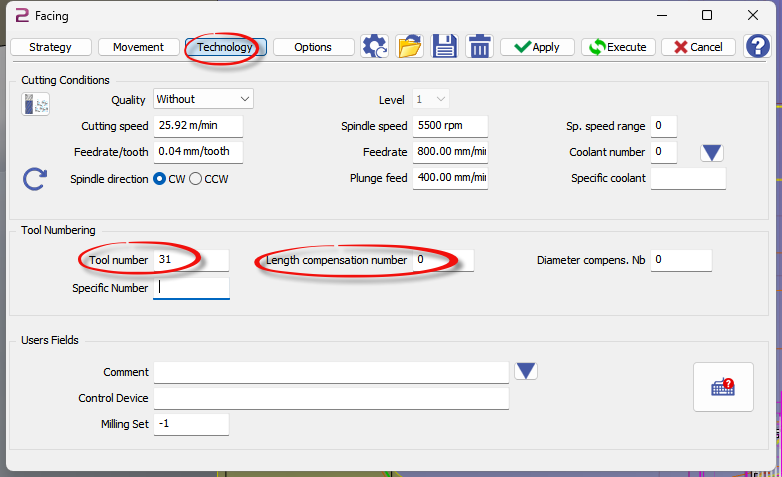

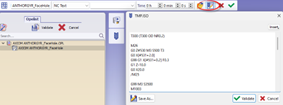

2 - Edit OPL

3 - Inside OPL put the correct tool numer and if needed add correct number for tool length compensation

| T3441 M36 S5000 G17 M8 G0 C0. X20. Y0.006 T41 |

|---|

| T3100 M36 S5000 G17 M8 G0 C0. X20. Y0.006 T31 |

|---|

Tool Path

Roughing

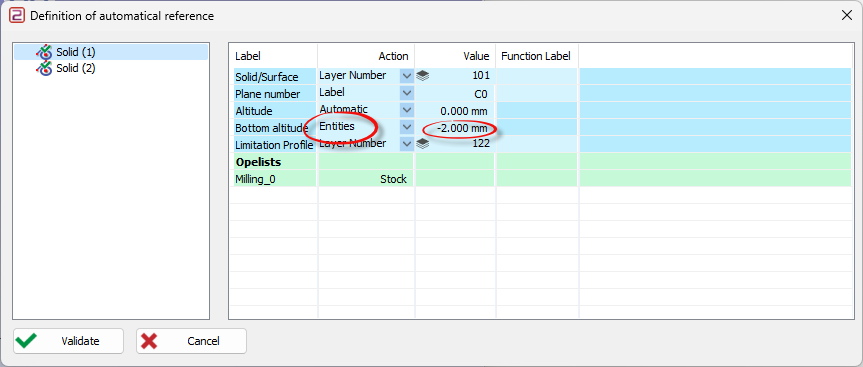

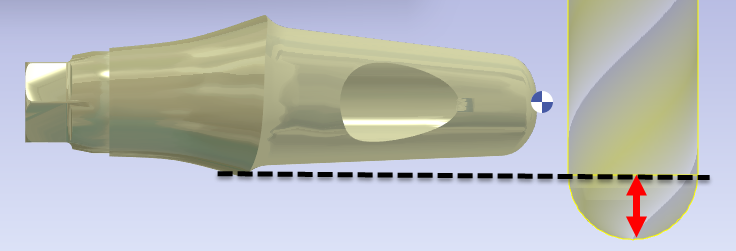

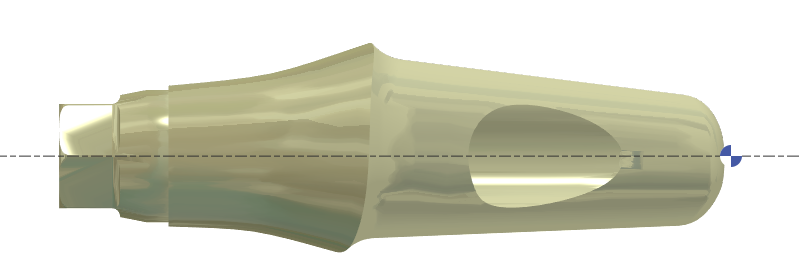

Reference (Geometry selection)  | Bottom Altitude = ENTITY Value must be Tool radius  |

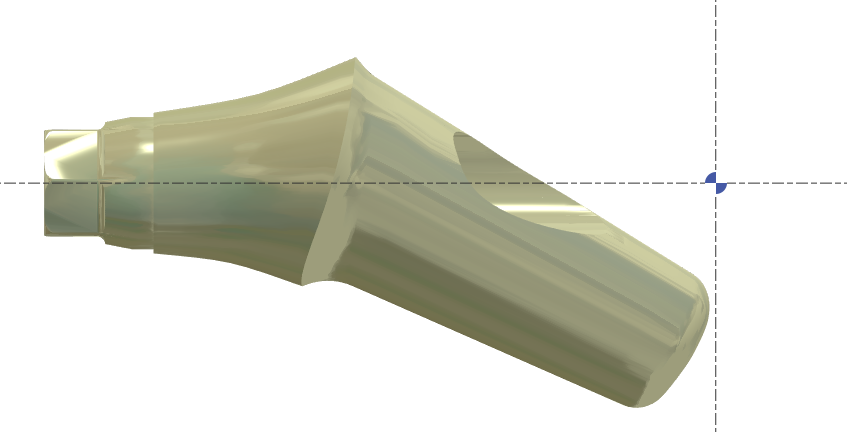

To save machining time is important to place abutment on position with minimum undercut - we can reduce number of pass

Correct placement minimum Z depth  | Not correct many pass in Z  |

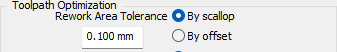

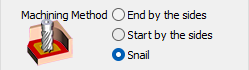

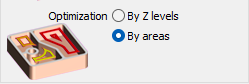

Setting to get the minimum air cutting

Stategy TAB | Movement TAB | Options TAB |

|---|---|---|

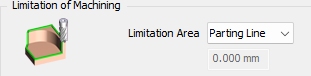

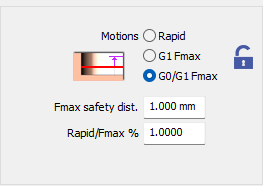

Automatique stop on the parting line. |  Rapid.Fmax % = 1 to have maximum of G0 for link between 2 path |  Value = 0.1 Here the stock is after turning operation so stock is very smooth no need to have small tolerance |

Force the toolpath to start from outside to inside | ||

To avoid retract mouvement. Tool work area by Area |

4Xs

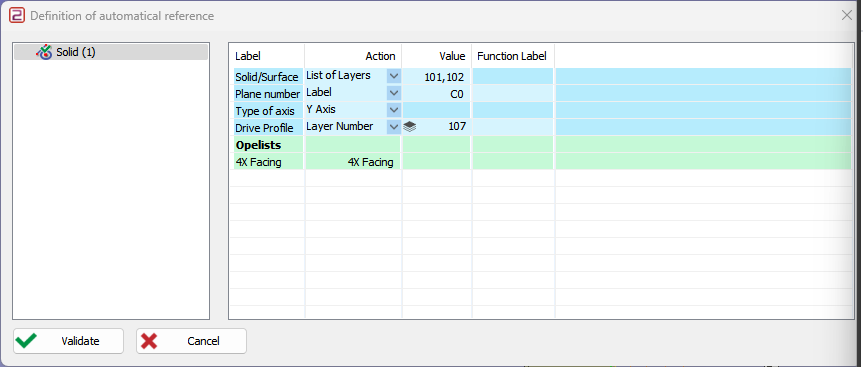

Automatic reference:

101: STL file + RED Cylinder to protect Connectic area

102: SOLID at the back to avoid to tuch occlusal face

107: Guide line used for 4Xs tool path - length can be adjust inside setting

NB: (without MTE)

|RSTATE|0|180.000000|

|RSTATE|1|270.000000|

Options TAB | |

|---|---|

| |

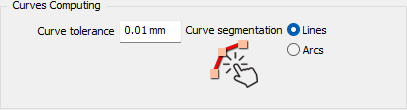

Curve tolerance = 0.01  | Curve Tolerance = 0.1  |

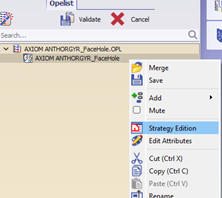

Edit Drilling OPERATION

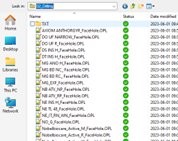

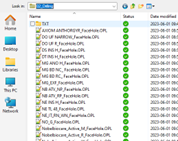

| ..\opelist\casm\02_Drilling  |

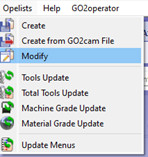

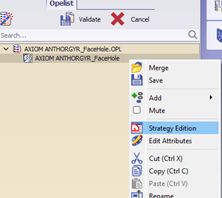

Right click to have the menu then “Strategy Edition”  | Click on the Icon in red  |

Change your NC codes – then save it  | Save the file in: ..\opelist\casm\02_Drilling |

Edit Connecting Area OPERATION

| ..\opelist\casm\08_Connecting Area  |

Right click to have the menu then “Strategy Edition”  | Click on the Icon in red  |

Change your NC codes – then save it  | Save the file in: ..\opelist\casm\0 8_Connecting Area |

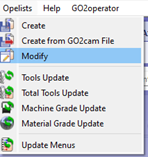

Change TOOL - Process will be change if no MTE

1 – Create your new tool in the DATABASE

2 – Inside MTE LOAD your tool

3 – Save FMO

4 – New file to check if tool is in the machine

5 – Edit OPL back turning and change tool (you can replace previous OPL or create new one)

Follow video!

V6.07.207

4XS Toolpath = ToolPath is more smooth, rotary speed of S1 is constant, so we can use 0.01 as tolerance

Minimum Diameter for protection of the connectic area