Lead in and Lead out angles and distances

Cycles: Straight Cut, Taper cutting, 4 Axes cnt / cnt, 4 Axes elt / elt, Specific

Definition

Management of the wire lead in and lead out.

Only Lead in parameters are explained but the principle is exactly the same for Lead out parameters.

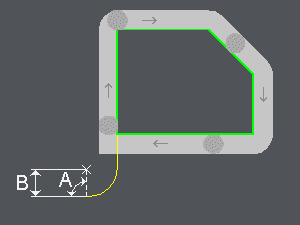

Lead in angle (A)

Angle generating the automatic approach point calculation (generally the wire threading point) if the approach distance is > 0.

It is relative to the tangent of the first profile element (Angle=0 places the point in the extension of the first element) and on the opposite side of the one given by "Part position".

It is advised to use an angle of 90 degrees so that the machine can perform a correct compensation and taper engagement.

Lead in distance (B)

Distance generating the automatic approach point calculation (generally the wire threading point).

It is relative to the direction defined by "Lead in Angle" and must be at least equal to the offset value so that the machine can make a correct engagement compensation.