Lead in and Lead out Characteristics

Cycle: Threading

Definition

These parameters manage the lead in and lead out movements of the tool.

a. First define the value of the radius for the lead in and the lead out (the 2 values can be different).

If this value is 0, there is no radius done and the other parameters are not available.

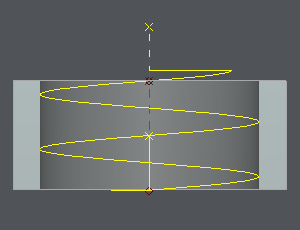

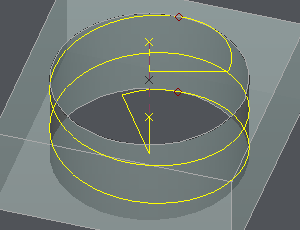

In this example, the diameter of machining is 10 mm, the leadin and lead out radii are 7.5 mm.

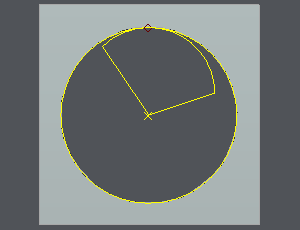

b. You can define an angle of aperture for the radius.

This angle define the length of the radius, in the following example the leadin radius is 90°, it is a quarter of circle.

The lead out angle is only 45 °.

c. You can finally define if the radius is constant or evolutive regarding Z axis.

In the example, the lead in radius is evolutive whereas the lead out radius is constant.