Toolpath Optimization

Cycles: Facing Pocket, Pocket, Pocket Rework, Pocket+contour, millyuGO, Roughing/Reworking, Facing Roughing, Pocket (Shape), Flat Face Finish

Definition

GO2cam advanced pocketting cycles offer several solutions to make the toolpath as safe as possible, by optimizing toolpaths, by decreasing jerks, by reducing feedrate.

All these options enable to save time and increase the tool life and the machining quality.

Optimization

Rework Zone Tolerance

Ability to limitate the reworking areas.

More details here: Rework Zone Tolerance

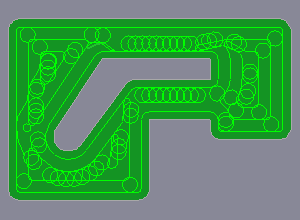

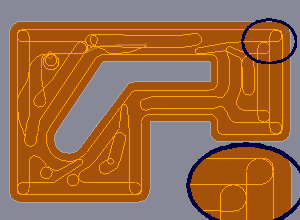

Protection: treatment of the stepoverTreat maxi stepoverIf the cutting conditions are severe for the tool (full width cut or high feedrate), GO2cam offers 2 solutions: Feedrate Reduction Ability to program reduction of feedrate regarding the stepover value. More details here: Treat Maxi Stepover Trochoidal Machining Trochoidal motions are defined at critical areas regarding the stepover value. More details here: Treat Maxi Stepover |  |

Protection: treatment of the changes of direction.Type of HSM RadiusThis parameter enables the programming of Alpha or Omega loops where changes of direction are done. Alpha:  Omega:  It avoids jerks and shocks for the spindle and the tool. More details here: Type of HSM Radius |  |