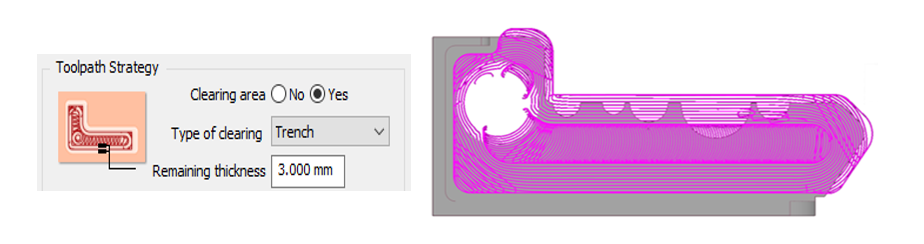

Toolpath Strategy

Cycle: millyuGo

Introduction

| millyuGO® includes toolpath strategies that prevent thin wall formation and maintain both tool integrity and material rigidity. Details about the millyuGO® cycle, its benefits and an example video can be found by clicking the link here. |

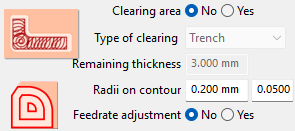

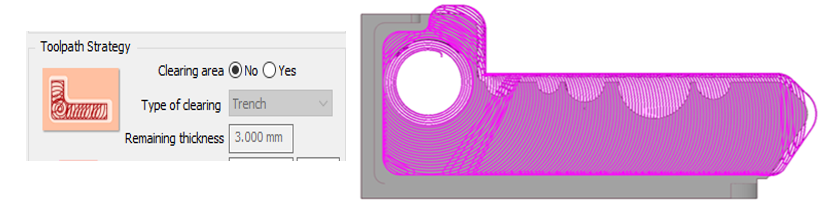

No Clearing area | The millyuGO® toolpath is optimised for the whole profile/zone selected. | ||

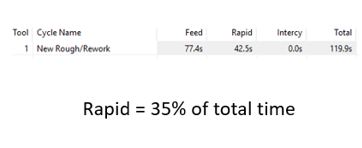

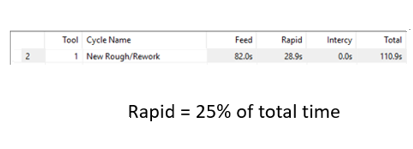

Trench |  Avoid thin sheet | Trench: Generates a trench of thickness defined by the Remaining thickness field along the wall. This is especially useful when machining thin walls. The trench ensures rigidity of the wall for proper machining. The cycle creates 2 areas with the wall contour machined in the end with minimal forces. In some cases, it limits the rapid toolpaths. | |

|  | ||

|  | ||

Avoid thin sheet: This parameter computes toolpaths to avoid generation of thin sheets with the stock. A minimum thickness is ensured for rigidity and is machined in a single pass within the toolpath. | |||

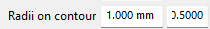

| Radii on contour: The parameter defines a radii value to be considered during toolpath computation for contours. This allows mitigation of sharp corners. The first field defines the contour radius in the toolpath. The second field is the ratio of the contour radius to the selected tool radius. | ||

No |  Yes | Feedrate adjustment: If set to Yes, the feedrate is adjusted in real time to compensate for the varying load on the tool during machining. This is to ensure that the load sustained by the tool is almost constant at all times to minimize tool wear. | |