XY Step - Ae

Cycle: Slotting, Chamfering, Interpolation, Plunge Pocketing, Plunge Contouring

Definition

This parameter defines the incremental distance between consecutive tool passes in the XY plane. It determines the lateral spacing of machining paths or plunge points according to the programmed strategy.

A smaller value produces denser toolpaths for finer surface quality, while a larger value increases spacing for faster material removal.

GO2cam automatically adjusts the final pass to ensure full coverage of the defined machining width.

| Enter a XY Step (Ae) value in Chamfering cycle, the number of passes depends on the Width defined. The first passes respect the increment, the last pass is calculated by GO2cam. |

| Enter XY Step (Ae) in Plunge Pocketing and Plunge Contouring. It defines the horizontal spacing between successive plunges, determining the density of plunge points within the pocket area. |

| In Slotting, the user selects the appropriate tool, defines the XY Thickness to specify the remaining stock, and sets the XY Step (Ae) value to control the lateral spacing of tool passes along the slot. XY Thickness: Defines the thickness of material to be removed laterally during machining. |

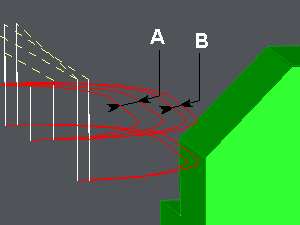

Example:

Width = 10 mm There are three passes, two passes with a 4 mm increment (A), the last one with a 2 mm increment (B) calculated by GO2cam. |  |