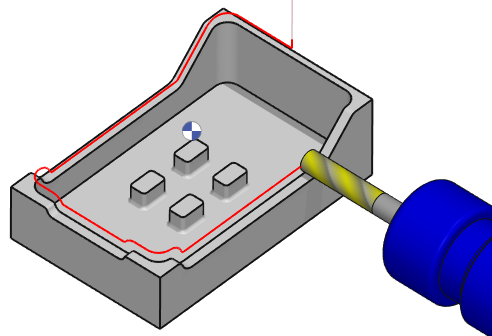

5X Swarf on Single profile

| Simple strategy - you only need to define the side of toolpath according to the geometry. |

Key Points

|  |

Technical Reminder about SWARF cutting: Side Wall Axial Relief Feed.

The goal is to produce the target surface with only one cut, using the whole flute length of the tool. The motivation is:

better surface finish quality (without hand finish),

shorter finish cycle time,

full access of machining areas through simultaneous 5 axis vector orientation,

constant cutting conditions (increased material removal, constant (low) cutting force).

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | Toolpath offset | |

Allowances | Z Stock allowance | Normal Stock allowance |

Movement Parameters

Dialog Area | Parameters | |

Z Approach and Retract | Rapid plane alt. | Safety distance |

XY Approach and Retract | Lead in length | Lead out length |

Lead in Strategy | Lead out Strategy | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |

| |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |