Coolant

Introduction

Coolant in machining processes is a specialized fluid used to cool and lubricate cutting tools and workpieces during various machining operations. Its key functions include dissipating heat to prevent overheating, providing lubrication to reduce friction and tool wear, aiding in chip evacuation, preventing corrosion, improving surface finish and reducing friction-induced vibration.

Different types of coolants are chosen based on the material and process requirements, and they are delivered to the machining zone through various methods to optimize their effectiveness in enhancing machining efficiency, quality, and safety.

Defining Coolant

There are three ways to define coolant numbers in GO2cam:

| ||

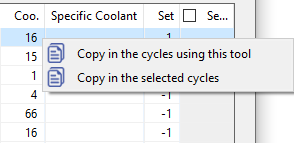

In the List called Tool, you can find a column called ‘Coo.’ for Coolant. You can enter the numbers easily for each operation. | ||

| A new ability in V6.11: multiple copy of coolant number, by a right-click in the cell.

|  |

But to be taken, the techno page of each operation must be set to 1. | ||

Predefined coolant numbers

You can define your customized predefined list of coolant numbers.

Automatically, in the folder ‘mac’, a file my_machine.cfg is created. It enables to configure the machine comments, origins and coolants. → Once the cfg file created, a predefined list is accessible in the Technology page. |