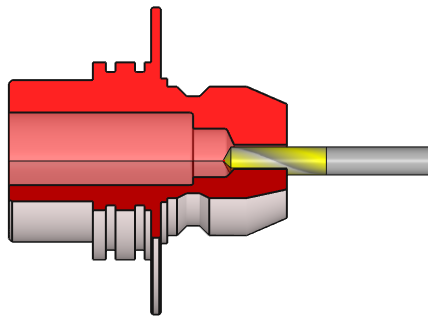

Drilling - Turning

| Drilling operation on a lathe machine. |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | Piloted point | Pilot type |

Extra Options | ||

Machining Strategy | Drilling | Depth calculation |

Lead out distance | Drilling Depth | |

Pass Depth | Last pass depth | |

Hole diameter (excentration of the tool) | Back by the center axis | |

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | Safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Level |

Cutting speed | Spindle speed | |

Speed range | Feedrate per tooth | |

Feedrate | Feedrate in Z | |

Spindle direction | Rotation Speed of Tool | |

Tool Numbering | Tool number | Specific Number |

Length compens. nb | ||

Users Fields | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||