FAQ - Holes

How to assign a user hole to a shape for multi-stages holes machining? | ||

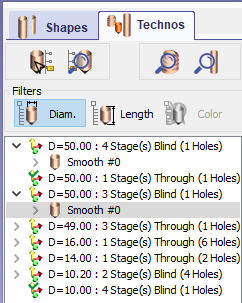

During the Holes recognition step, upon selecting the required hole(for instance we will choose a 3 stage hole), we have two possibilities to assign a user hole to the selection. |  | |

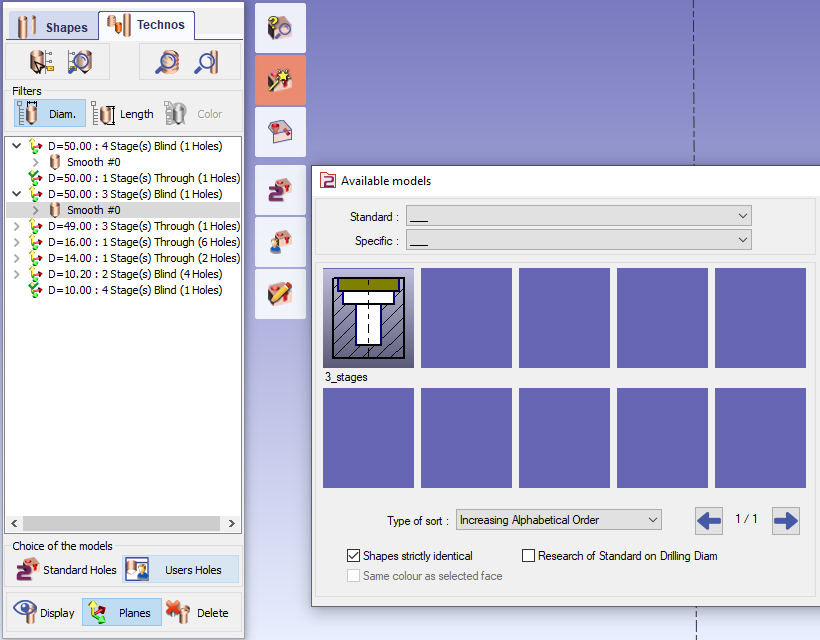

1/ If User hole templates are already available, we can simply click on Users Holes. The list of available compatible models is opened; GO2cam scans in all the different libraries to provide the list. If only one model is compatible, you can apply it automatically without opening the table! For this, in Software configurations, in the Holes section, under 'Automatical Recognition on a Solid' Model, ensure to select 'Automatical applying if one available model' |  | |

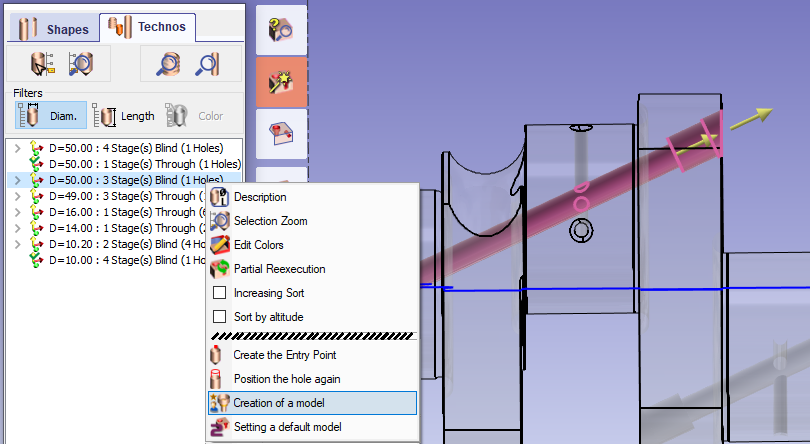

2/ If User hole templates are not available, we can right-click on the required hole and then choose 'Creation of a model'. This function enables to create the base of the model:

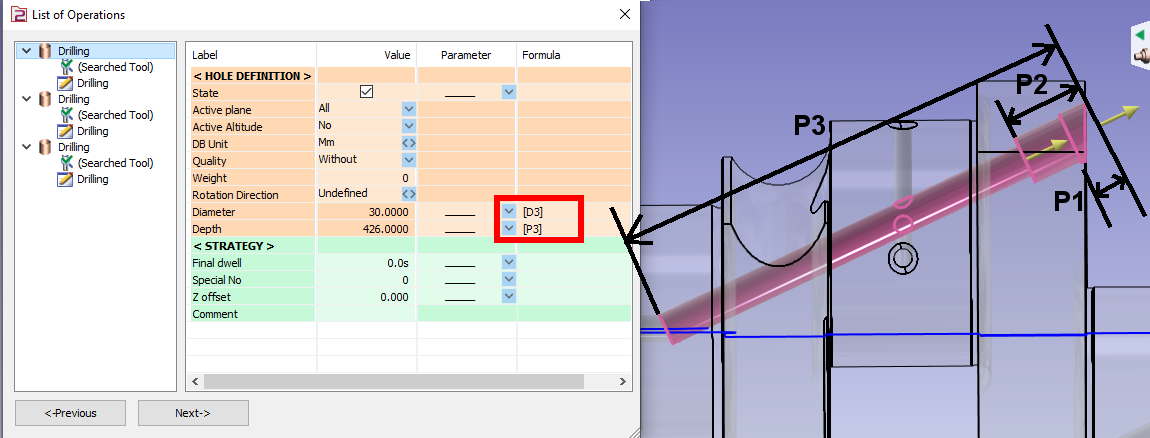

If you click on Users Holes when no matching template is available, you will be prompted with a dialog window where you can directly select Create a model. For the depths on the shape at this point, we have no access to the cycle parameters: the start of machining and depth are set automatically according to the type of operation! For instance:

As for the list of operations, they are arranged from the smaller to the bigger diameter. (D3>D2>D1) We can click on next and finally name and save the model after which it will be applied to the selected hole in the technos tab. |   | |

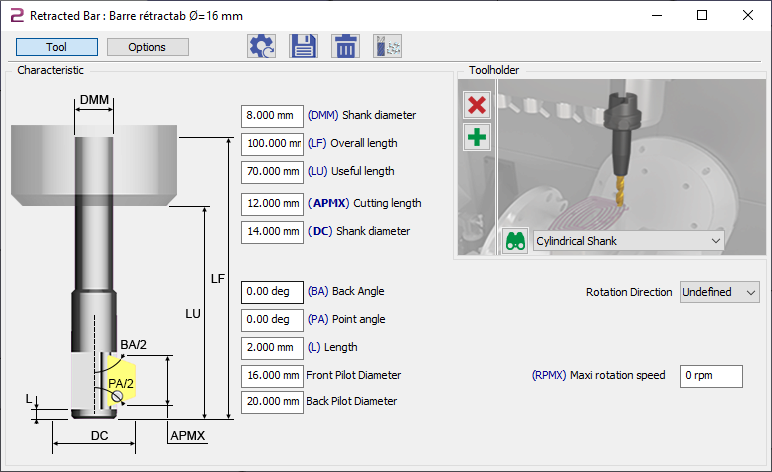

How to program a top and back face counterboring? | |

If the 2 top and back counterbores have the same diameter, you can use the same tool and a single cycle! | |

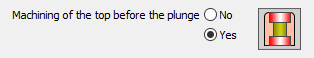

To do a counter boring operation, you have to tick Yes to the 'Machining of the top before plunge' parameter, this option will allow you to modify the Depth/Ref and 'Depth' parameters field.  | |

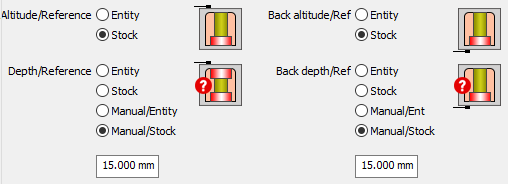

Then we focus on how to set references: Altitude and Depth

| |

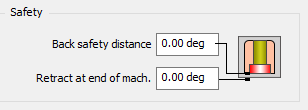

Lastly, we have define the back safety distance and retract at end of machining for the protection of the tool and the machined faces. | |

Your Turn!! | |

File: Pièce en U.PCE | |

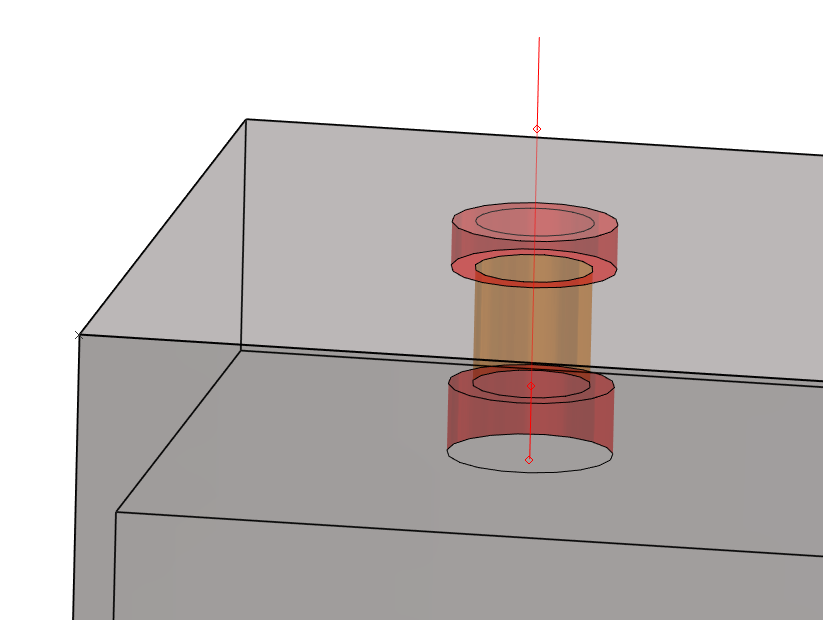

Open the ‘Pièce en U.PCE’ The 2 counterbores have the same diameter (14mm) that are 4 mm deep on the top face and 6 mm deep on the back face. | |

Switch to milling.

|  |

The end result must be the same as on the right. | |