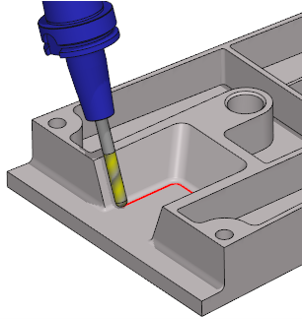

5X Swarf Auto

| 5 axis simultaneous operation realized with the flank of the tool. It is used for machining fluid parts for turbo-engines or aeronautical parts, such as integral elements. It produces the target surface in only one cut, using the whole flute length of the tool. This cycle offers powerful automatic strategies compared to manual swarf cutting operation. |

Key Points

|  |

Technical Reminder about SWARF cutting: Side Wall Axial Relief Feed.

The goal is to produce the target surface with only one cut, using the whole flute length of the tool. The motivation is:

better surface finish quality (without hand finish),

shorter finish cycle time,

full access of machining areas through simultaneous 5 axis vector orientation,

constant cutting conditions (increased material removal, constant (low) cutting force).

▶️ You can watch a video where this cycle is being used: https://vimeo.com/850444783?share=copy

|