Alternate Machining

Cycle: Direct grooving

Definition

Ability to choose the type of toolpaths generated for the Z level grooving.

You can choose between 4 options:

| Yes |

| No |

| Continuous optimized |

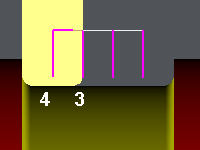

Yes means that the first plunge is done at the center, then the flanks are machined one after another.

First plunge | One flank is completely machined | Then, the other flank is done |

|  |  |

No means that the first plunge is done on one flank and then the following passes are programmed in one direction.

First plunge on one flank | Then, the tool follows only one direction for machining | |

|  |  |

Continuous Optimized: This option optimizes the pass in a way such that the machining of the remaining material is carried out just after the groove machining and this is repeated for all the grooves in the profile.

This application is very useful especially for Swiss Machining since this reduces the need to have the part retract back in the guide bush for machining of the remaining materials since it is done in one go.