Dwell

Cycle: Direct Grooving, Z Level, Zig Zag, Wtype, O Ring Type, Centering, Drilling, Drilling Reaming, Tapping, Die Threading, Parting, Pecking, Chamfering, Knurling

Definition

Ability to program dwell during the toolpath, according to several parameters:

Dwell Depth

Dwell Unit

Dwell

Final Dwell

Settings

Choose first the unit of the dwell: it can be expressed either in seconds or in revolution.

Then you can define the Dwell Depth, which is the distance between 2 dwells.

Dwell is the value in seconds or revolution, the code is often G04 with a letter (X or U for Fanuc, F for Num for example).

Final Dwell enables to define a different value at the end, to make a better finish at last pass.

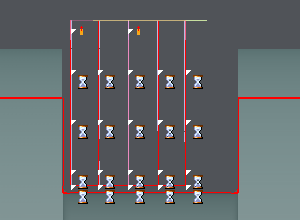

The dwell defined are displayed on the screen with the hourglass symbol as shown on the picture below.

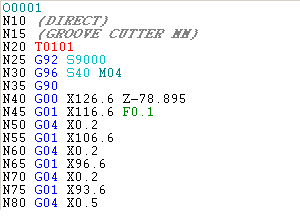

In this example:

| |

|  |

Special case for Direct, Z Level and Wtype Grooving operations.

The dwell defined in strategy is not applied on all the toolpath for thos 3 operations. In a way, we can consider that the roughing passes are decomposed in 2 paths:

‘roughing' passes: vertical plunges are done by the tool and there the dwell can be applied.

‘pre-finishing' pass: the tool realizes one path on the profile after each roughing plunge. This pass is triggered by the parameter ‘Profile Machining’.