Information for VARs

This page is dedicated to the VARs installing and configuring NC control at customers'

Structure of NCcontrol

The necessary files and structure of directories is explained in the downloadable Powerpoint Presentation, through two diagrams.

Configuration of Customer’s PC

When you define a machine at customer’s:

You must create a directory for each machine in nccontrol\programdata\NC2check\machines

Machine file: this directory must be defined in the machine file, in page post-processor.

Specific post-processor: information must be defined in the PP, especially in the procedure NCcontrolDefineController. Check the list of variables here: Variables for CNC Controllers.

Data to download

The xml file exportNC is a file that contains the informations of MTE machine Kinematics plus Origins List and Tool Offsets. The aim of this file is to give the necessary information to NC2check to allow the analyze and treatment of the NC file send according to it. | |

A xml file is exported while generating NCfile. The file will have the same name as the NC file but with extension “NCC” and in the same directory of NC output. | |

Samples | NCC_test_basic.GMZ NCC_PRISMS.GMZ NCC_Hermle_C250.GMZ HEAD_HEAD_45_TEST.GMZ |

Rules for MCG files

There are two ma,ndatory rules in the creation of the 3D kinematics machine file.

The main machine frame component must be named Body (Capital B is mandatory).

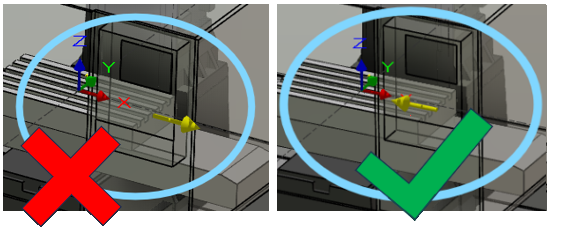

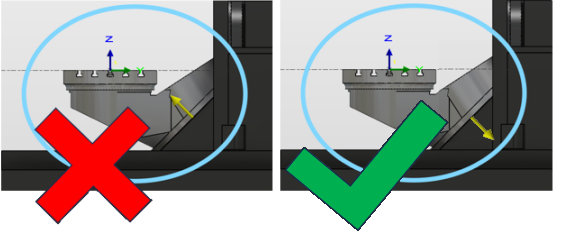

The orientation/direction of axis is now fundamental.

Linear Axis  | Rotary Axis  |