Main Chuck and Stock Positioning

Introduction

The positioning of main chuck should be defined to ensure the part is properly machined.

At the start of machining the stock is pushed by the bar feeder and the positioning of the parting tool stops the bar.

At this moment, the main spindle unclamps the bar, retracts back to reach the position to have enough stock overrun to machine the part and clamps the bar to machine the part.

The minimum stock overrun value is discussed in 2 cases below:

Case 1 : Without Guide Bush

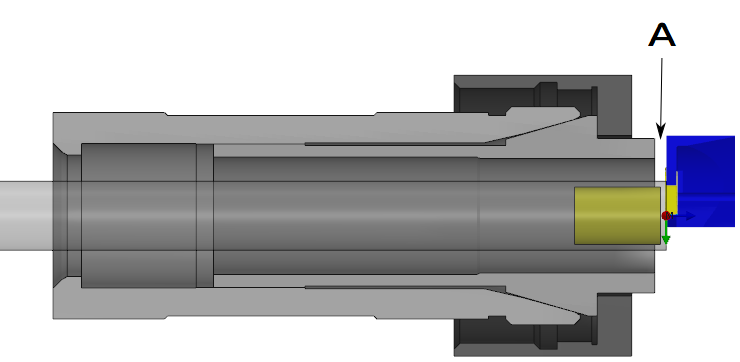

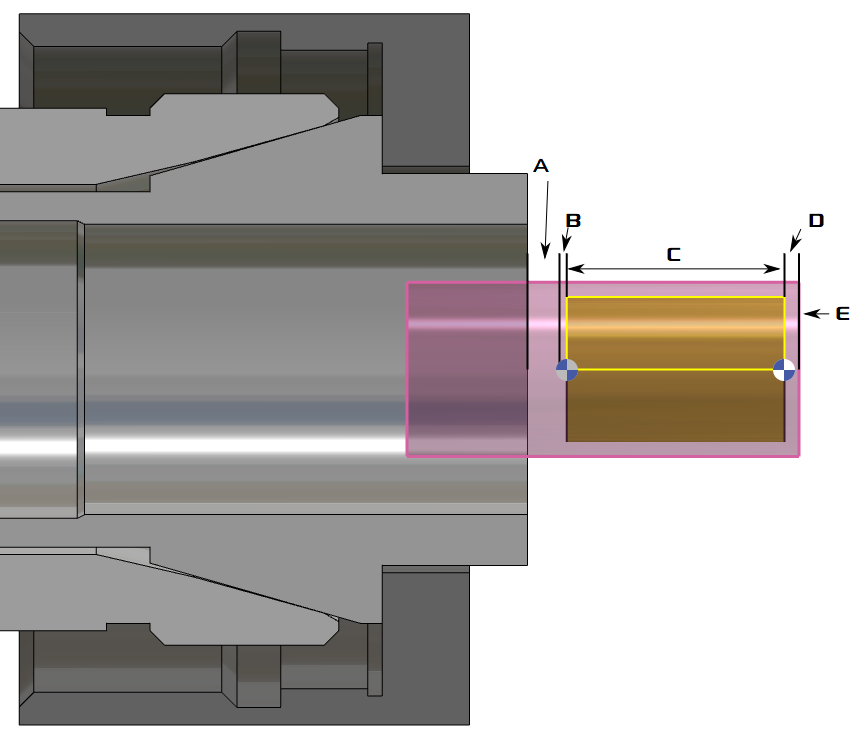

Minimum stock overrun to machine the part : Allowance for facing + finish part length + parting allowance + parting tool width Since the maximum position of the main spindle can not reach the parting tool, we have to add the distance between the parting tool and the nose of the main spindle to the overrun position. We can also add a safety value to be sure to not have over travelling during machining. This safety value should not be too much otherwise the length of the unmachined bar will be greater. |  A - Distance between parting tool and maximum position of main spindle |

Sample example with values :

The value of overrun should be more than 20.7 mm |  A - Parting tool width B - Parting allowance C - Finish Part Length D - Allowance for facing E - Reference parting tool |

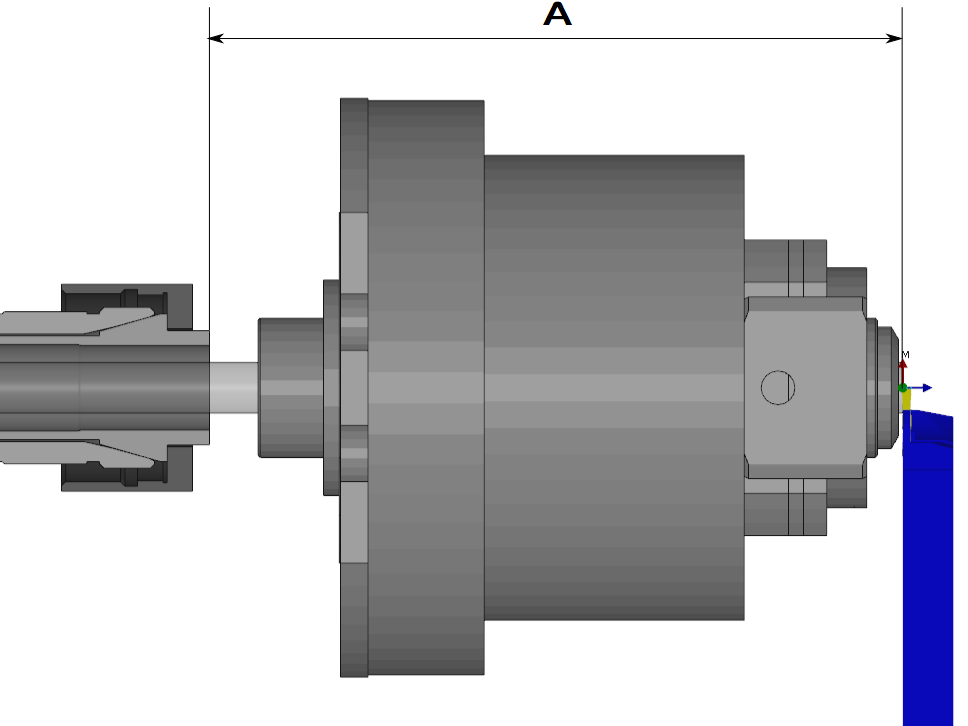

Case 2 : With Guide Bush

The computed rule is the same but as there is a guide bush, the distance between the parting tool and the nose of main spindle is bigger. Sample example with values :

The value of overrun should be more than 182.7 mm |  A - Distance between parting tool and maximum position of main spindle |