Setting Stock-Chuck

| This command allows the calculation of the position of stock in the chuck, especially useful for Bar Turning. |

There are some differences in the Turning and in the Swiss Machining modules, that we describe below.

1. Turning Modules

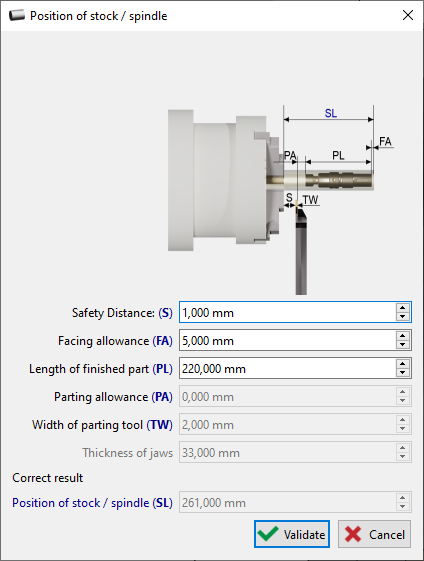

We calculate the distance between the chuck nose and the end of the part. For this, some values are recovered in the part and others are calculated:

All that information is displayed in the dialog and we calculate the result Position of Stock/Spindle (SL). There is also a treatment of mistakes:

|  |

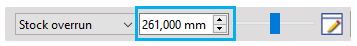

When we validate the dialog, the value is automatically written in the dialog area. This value can be considered as the minimum position necessary to machine correctly the part. |  |

2. Swiss Machining Module

In Swiss Machining, the calculation is the same as in Turning module except for the Distance sliding headstock/origin (ML), we calculate the distance between sliding headstock in maxi position and the end of part.

For the ML value, we read the machine kinematics for the distance of sliding headstock. It must be defined in maxi position in the MCG file to be calculated correctly. |  |