Stock Management

Stock Definition in Manufacturing

Stock serves as the foundational element in the manufacturing process. Before generating toolpaths, it must be precisely defined to represent the raw material’s initial state, which will be machined to meet final design specifications.

Functions of Stock in GO2cam

Machining Strategy Planning

The software calculates optimal toolpaths based on the stock’s shape, dimensions, and material properties, ensuring precision and minimizing waste.

Process Simulation

By defining the stock, users can simulate material removal at each stage, helping detect potential machining issues and make necessary adjustments.

Efficiency Optimization

Stock configuration enables optimized cutting sequences, tool selection, and machining parameters, improving both speed and accuracy in part production.

Chapter Overview

This section details the Stock Creation dialog, display settings, and configurable computing parameters.

Topics Covered:

Stock Management

What is Stock Management?

Stock management in GO2cam uses Parasolid-based B-rep modeling to simulate material removal. The process follows this computational logic:

1 NC code block → Generates 1 tool swept volume → Executes 1 Boolean subtraction (updating the stock).

Performance Considerations:

Large or complex toolpaths may require extended computation time due to accumulated Boolean operations.

In rare cases, extremely detailed toolpaths can lead to instability or failure.

For improved efficiency, Mesh Stock Modelling is available as an alternative to traditional B-rep methods.

Stock Management: "What You See Is What You Get" (WYSIWYG):

The simulated stock precisely matches real-world machining results.

Ensures predictable material removal - every toolpath operation modifies the stock exactly as it would on the actual machine.

Delivers visual truth - the final displayed stock mirrors the physical workpiece after machining.

|  |

Stock Management vs. Dynamic Simulation

Feature | Stock Management | Dynamic Simulation |

Primary Focus | Only material removed by cutting movements is modeled. | Comprehensive machining environment analysis and Simulates all NC commands (cutting and non-cutting) |

Non-Cutting Movements | Ignores rapid movements | Includes rapid movements |

Fixtures & Tooling | Excluded (no holders, clamps, or vices) | Fully modeled (holders, clamps, machine components) |

Collision Detection | Not supported | Real-time collision checks (tools, holders, workpiece) |

Stock Display Option

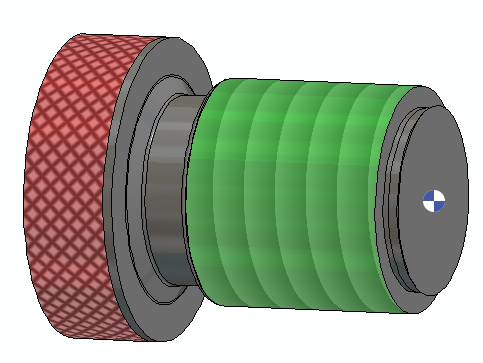

The tolerance of display of the solid and also the stock is defined in Tools / Options / Entities / General / Visual Comfort.(Same settings are accessible via the status bar in the bottom-right corner.) | |

For accurate visualization and simulation, realistic texture rendering is recommended for the following operations:

|  |

Rendering Texture of Tapping, Die Threading, Thread Whirling and Knurling are now available in the dynamic simulation!

Display of the Stock in the Program Window

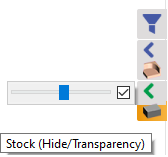

The display of the stock in the machining tab can be controlled with the Filters bar on the right.

|  |

The display of the dynamic stock removal during simulation can also be controlled. Click on the link below for additional information: