Stock Computing

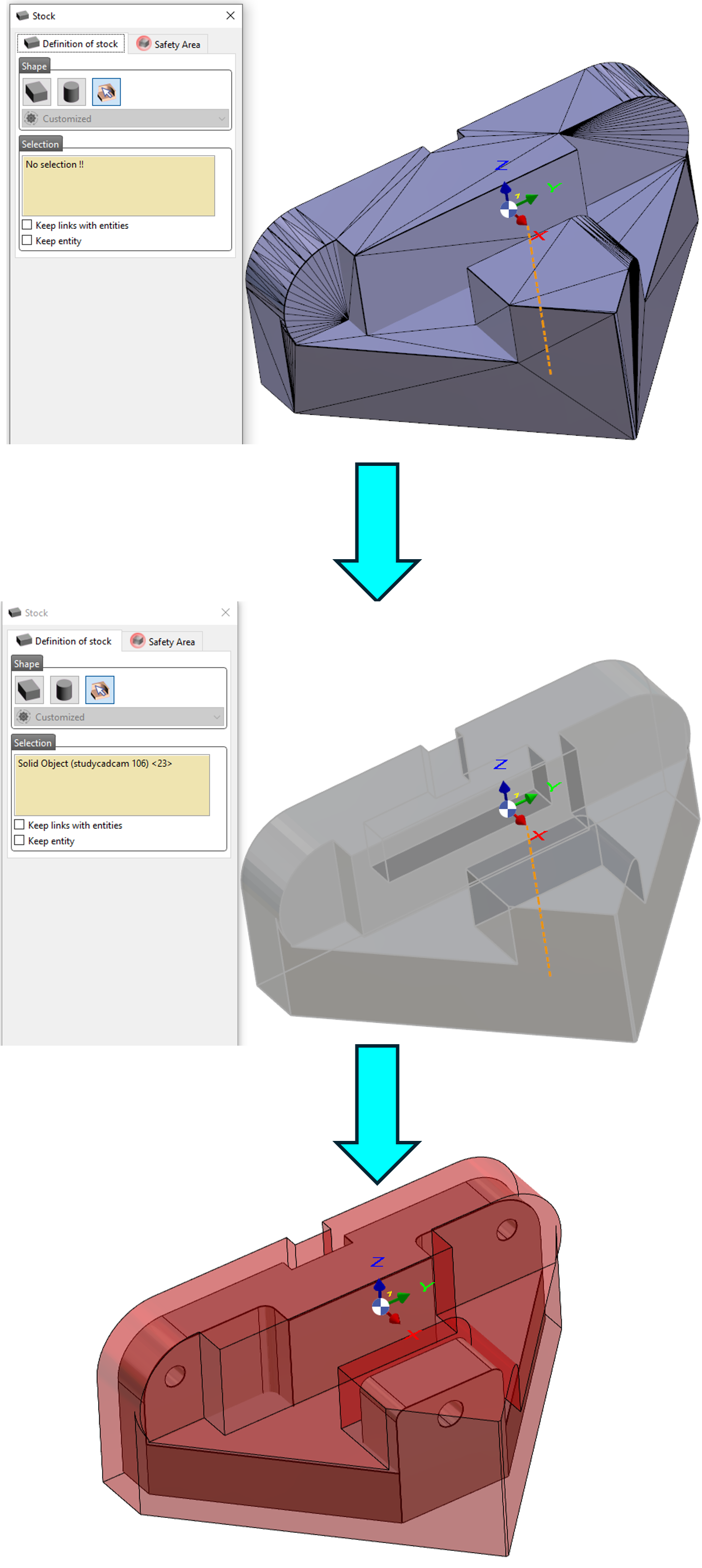

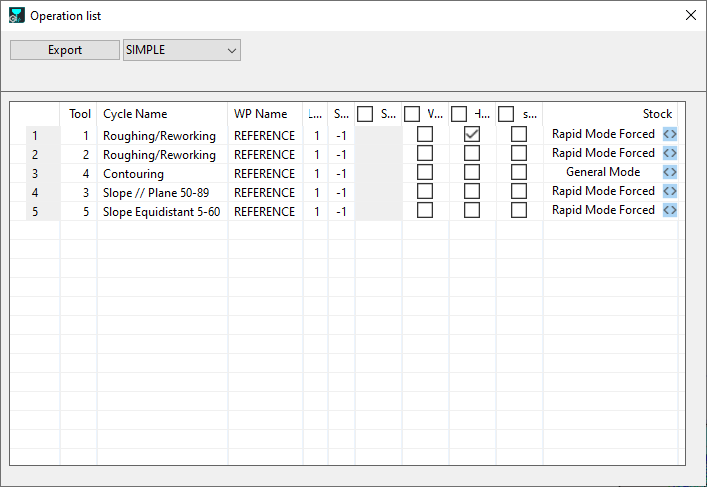

The General Computing Process

| ||

Initial Stock The software considers the state of the stock before the application of a cycle. | Cycle On the application of a cycle, the tool geometry and the toolpath generated are considered together. A swept volume of the tool along the toolpath is generated and this is the material that needs to be removed from the stock. | Final Stock A Boolean operation is carried out to remove the swept volume from the initial stock and generate the resulting stock. |

This process is repeated for each toolpath and can quickly require more processing power for complex topological surfaces. 1 tool movement generates 1 NC code line which produces 1 swept volume object for 1 Boolean operation. This is the reason why for solid Brep models(Parasolid), the visual stock computation is off by default for shape milling operations, else the computation time to compute all the toolpaths is long and in some cases may fail to compute. Rapid stock computation is available to compute the stock at a much faster rate with the operation being carried out on a mesh model, but this comes with a trade-off in the precision of the computed stock. | ||

The advantages and disadvantage of Brep and mesh models are listed below:

Solid (Brep) modeling | Mesh modeling | |

Pros |

|

|

Cons |

|

|

At any moment of the machining process, even once the toolpath are created, the shape of the stock can be modified in the machining tree and all the toolpath already calculated are automatically updated.

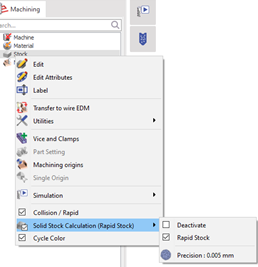

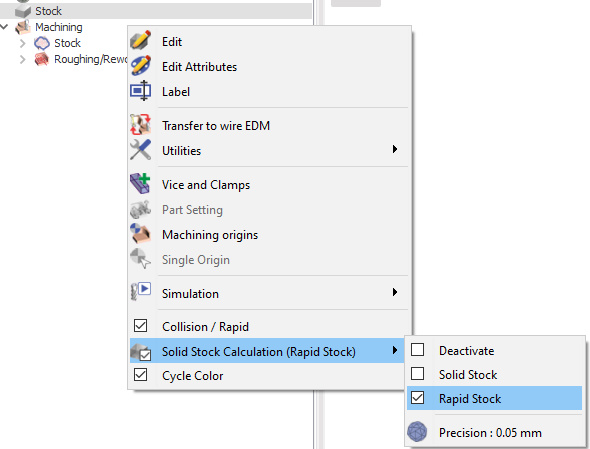

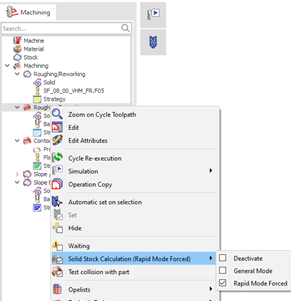

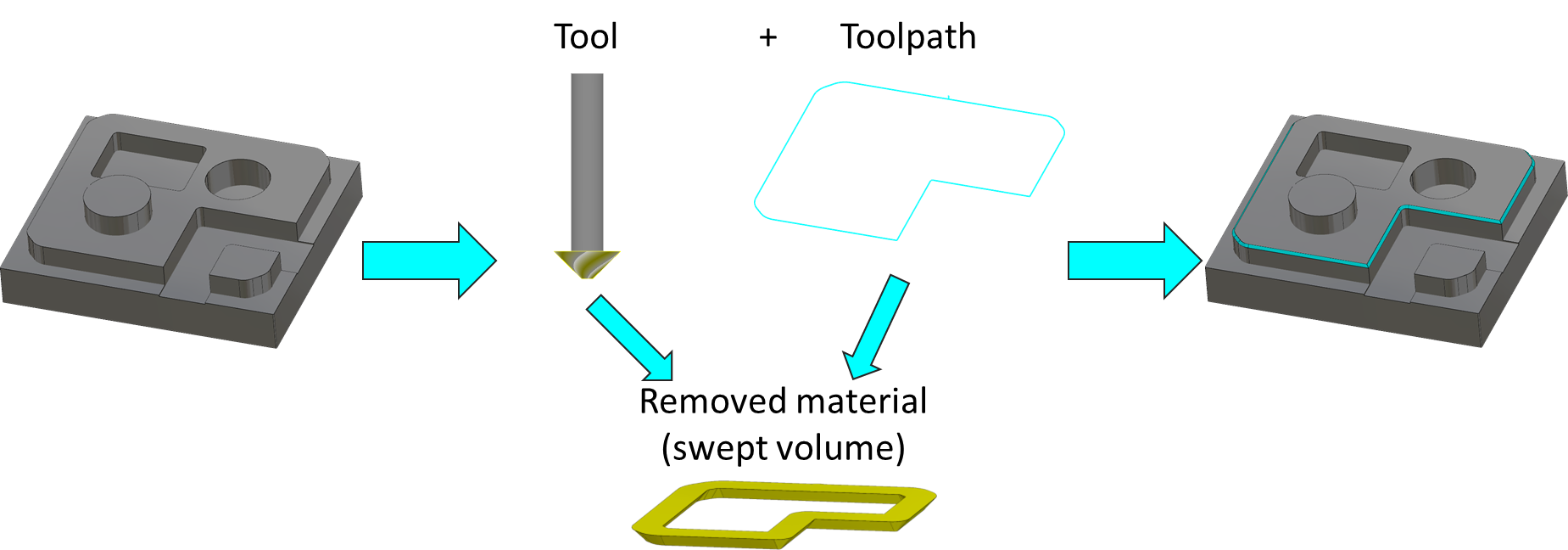

Options for Computing

In Milling, Turning, Swiss Machining and Wire EDM, the user can control the state of the stock computation ( solid or mesh) at 3 different levels. The table below summarizes the general behavior of the engine at the 3 levels:

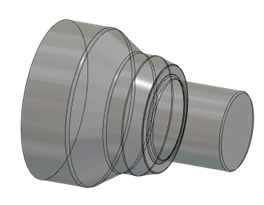

The original stock definition.

The stock management method

Individual cycle computation modes

ORIGINAL STOCK | SOLID (Cubic, Cylindric, Imported Brep File) | MESH (Imported STL File/ Designed) | ||

Stock management method | Solid stock | Rapid stock | Solid stock | Rapid stock |

Cycle 1 General Mode | Solid | Mesh | N/A | Mesh |

Cycle 2 General Mode | Solid | Mesh | N/A | Mesh |

Cycle 3 Rapid Mode forced | Mesh | Mesh | N/A | Mesh |

Cycle 4 General Mode | Mesh | Mesh | N/A | Mesh |

Behavior in Millturn

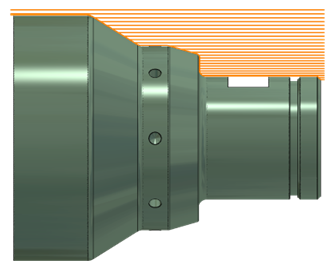

The complexity of turning parts is much less compared to milling operations. In GO2cam, there are 2 stock management for Turning; 2D Stock and 3D stock. For milling operations of millturn parts, only the 3D stock management engine is used. | 2D Stock  | 3D Stock  |

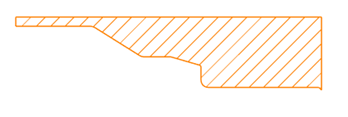

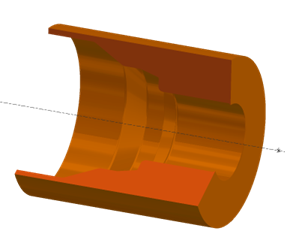

For turning operations, the removed material is computed in 2D and subtracted from the 2D stock. Due to the simplicity of the computation, the 2D material removal form is used to create a 3d volume through revolution which is then subtracted from the 3D stock. Turning operations are computed on the real stock, which means that all operations take into consideration the material removed from previous operations and generate optimized toolpaths based on that. Further details are provided below. | 2D removed material  2D Stock  | 3D removed material  3D Stock  |

For turning cycles, rapid stock computation is not necessary because the engine already manages the real stock material removal at a fast rate. Hence the stock management options for each cycles for turning operations is not available. For milling cycles applied on the axial plane, the stock management options for each cycle is still available and the computation is done exclusively on the 3D stock.  | Milling Cycle  | 3D removed material  3D Stock  |

Rest Material

In Milling and Wire EDM, the stock is the resulting calculation of the machining toolpaths. Rest Material is not taken into account at any step. For instance, you can program the same pocket operation twice: the toolpaths will be exactly the same. The second pocket does not know that a first similar operation was already made. | ||

3 axis milling is a special case: none of the operations manage the rest material except the roughing/reworking and millyuGO. The stock management is specific for 3 axis milling, please read the dedicated page: Stock Calculation for 3 Axis Milling | ||

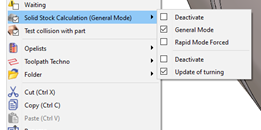

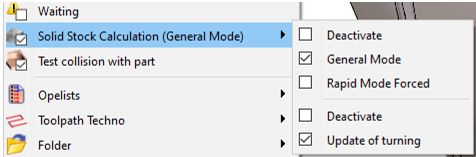

In Turning and Swiss Machining, each operation (except rare cases) manages the real stock. Here, the same roughing operation cannot be calculated twice! It means that the ‘shape’ of toolpaths always depends on the previous operation. When an axial milling cycle is applied on the turning stock shape, it is possible to take it into account for stock computation of next turning operations. For this, set on ‘Update of turning’ into the solid stock calculation option for each milling operation. |  The first half of this option controls whether the computation of the stock on the screen is considered as rapid/solid or not, as explained in the Stock conversion chapter. | |

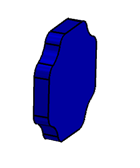

The second half controls the adjustment of the turning cycles to that of the milling cycle if ‘Update of turning’ is selected. |  Deactivate |  Update of turning |

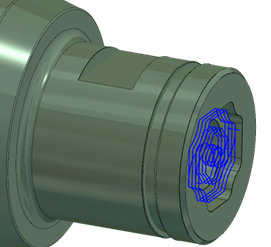

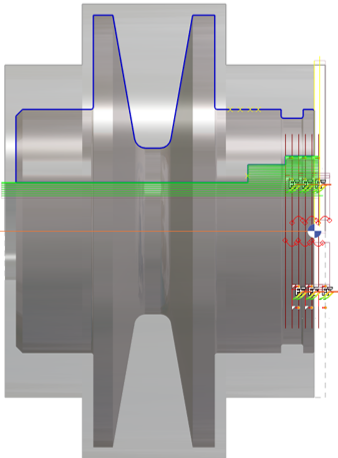

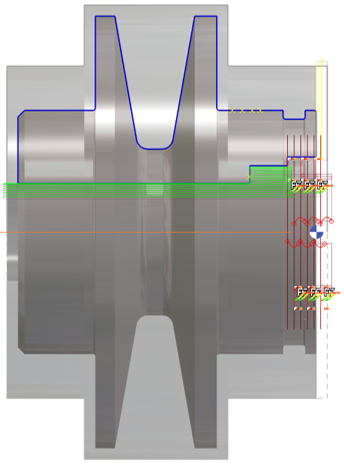

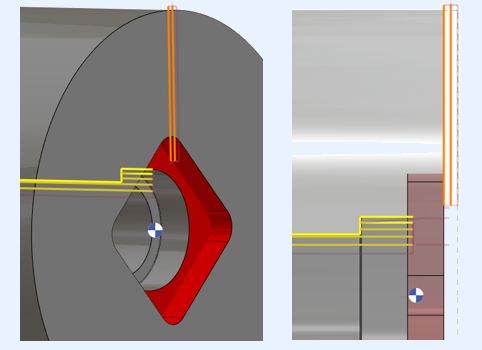

In the screenshots, the red area was machined by a milling pocket operation programmed in reference workplane. You can see that facing and reaming operations are shorter due to the remaining stock calculation.  | ▶️ You can watch a video demonstrating the effect of selecting ' Update of turning':  | |