Geometry Selection in Turning

In Turning, consider two main methods for the selection of geometry:

the General operations & Grooving operations: profiles are needed

the holes machining operations: points are needed.

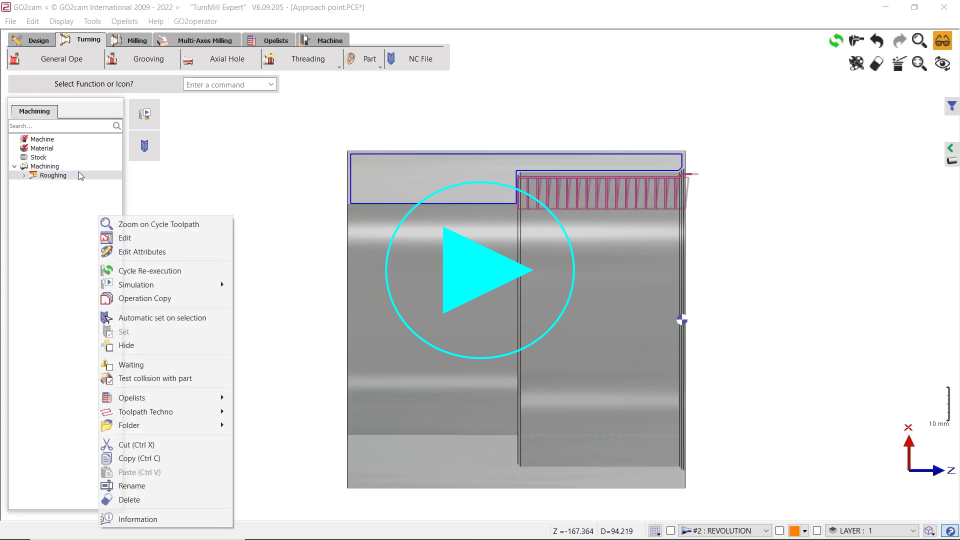

▶️ Watch a video at the bottom of page click here |

Selection for General Operations and Grooving

For either General Ope or Grooving cycles, the selection of geometry is carried out as follows:

General Ope | Grooving | |

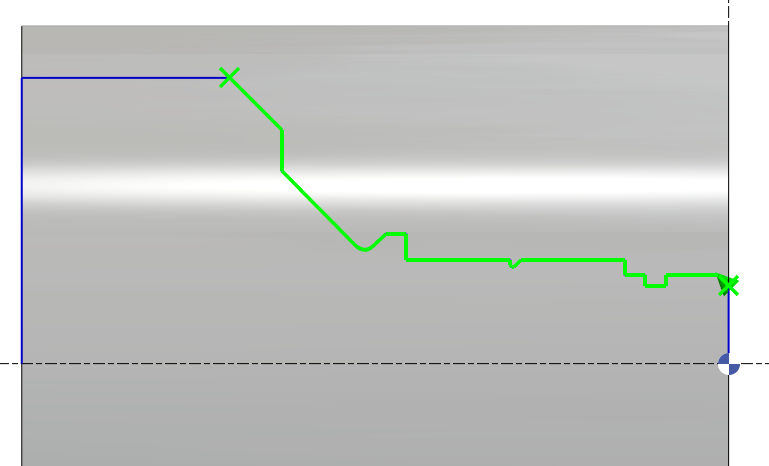

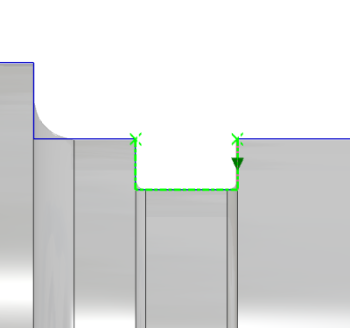

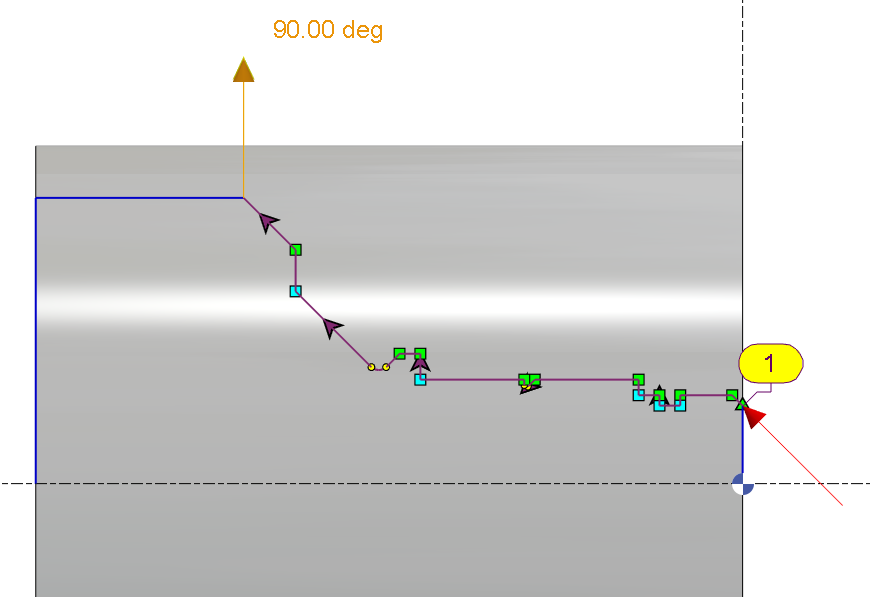

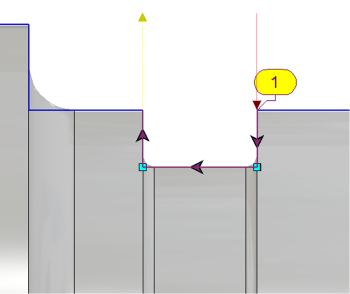

To create your cycle, first click on Geometry Selection.  Then determine the profile to machine by selecting the starting element up to the final element. |  |  |

Validate using the green tick. |

| |

The toolpath can also be inverted by selecting the Next option. |

| |

or Previous element. |

| |

Following this, the approach and return vectors can be managed, indicating the entry and exit paths based on the material to be removed. By default, the vectors are oriented tangentially to the first and last elements. They can be modified either by entering angle values in the designated fields or dynamically on the screen. |  |  |

Special Cases

Selection of Holes

Cycles: Centering, Drilling, Tapping

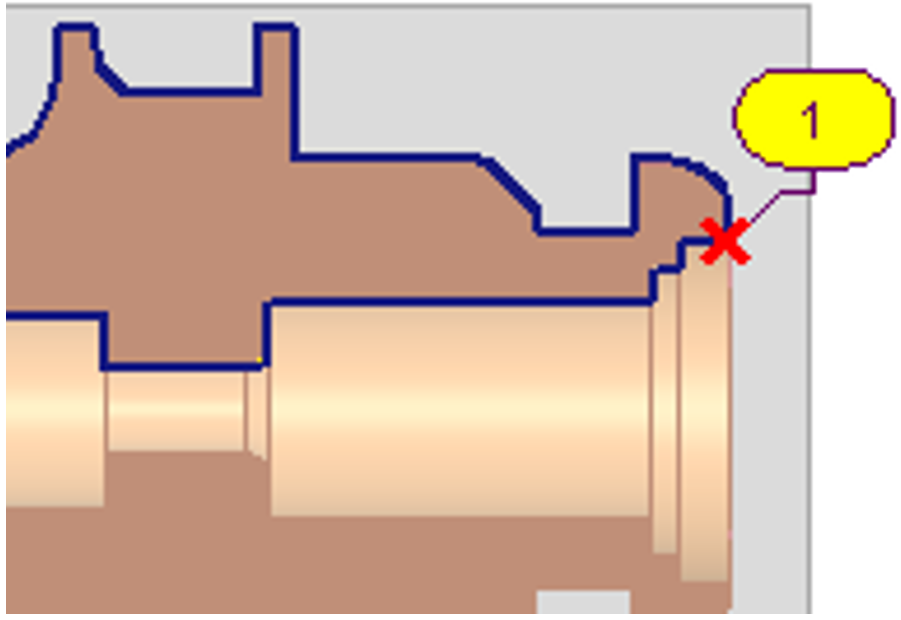

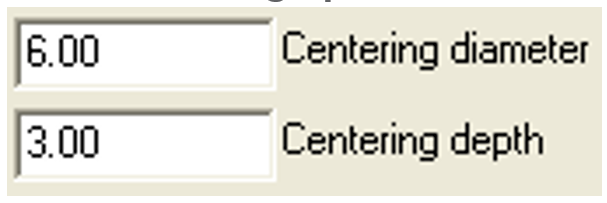

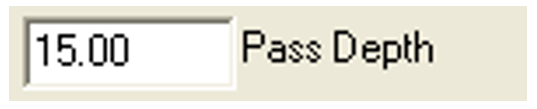

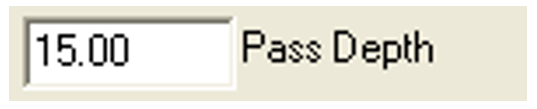

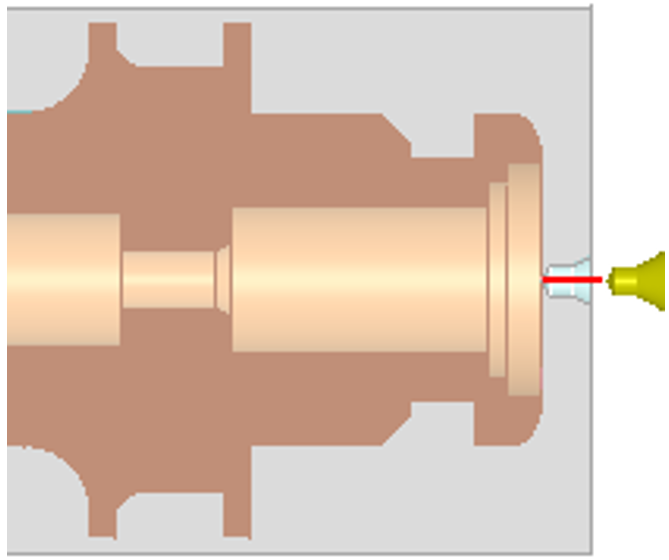

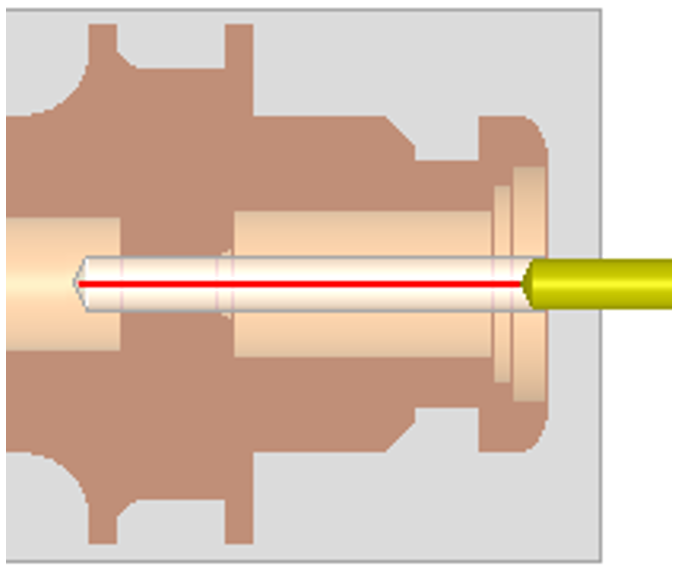

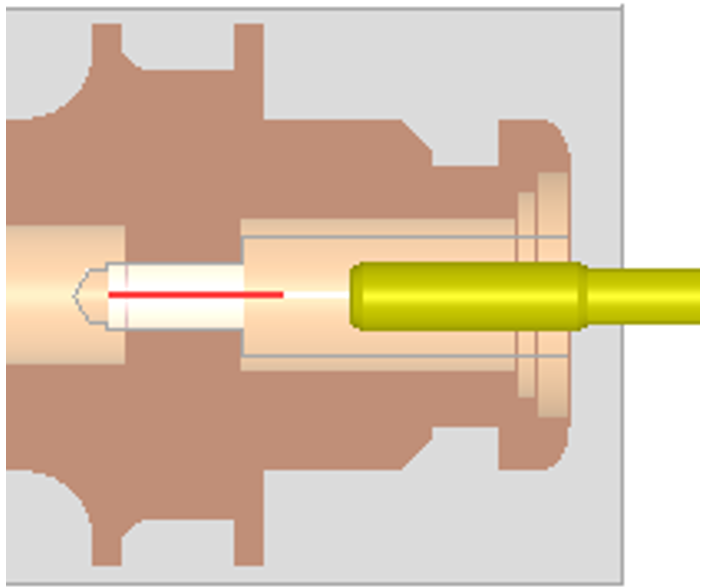

The geometry selection for these three cycles is specific: only a single point needs to be indicated. It is not necessary that the point is located on the hole axis. It can be anywhere on the geometry, as shown on the image on the right. The depth is determined in the strategy page, with the following parameters: |  | ||

Centering operation:  | Drilling operation:  | Tapping operation:  | |

|  |  | |

.png?inst-v=b44e98da-ee35-4dae-9eb1-dcda821d3f9a)