WanaGO

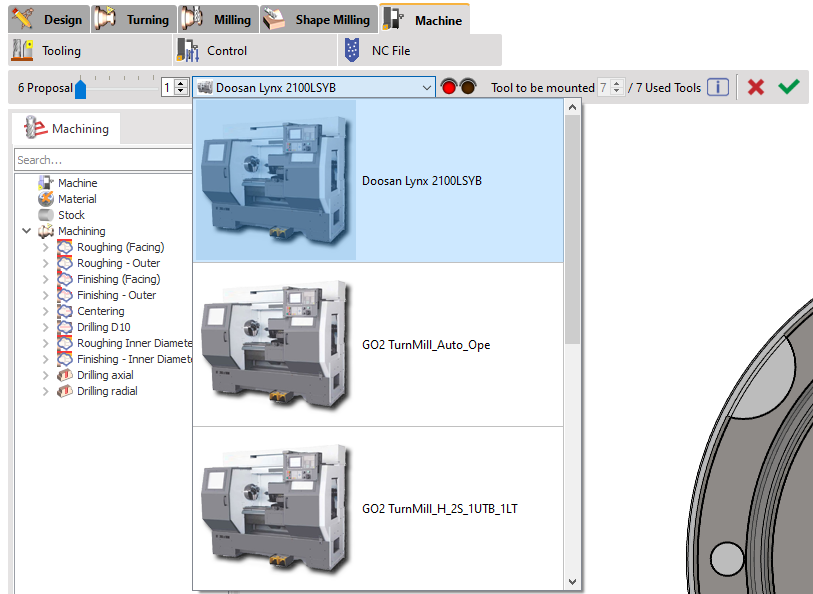

| The MTE module includes a feature called WanaGO (Workshop Analysis) that automates machine selection. This process considers the part's programming, required tools, and workshop data. The core concept is to program a part without specifying tools or a machine. WanaGO then analyzes available machines to find the best fit. |