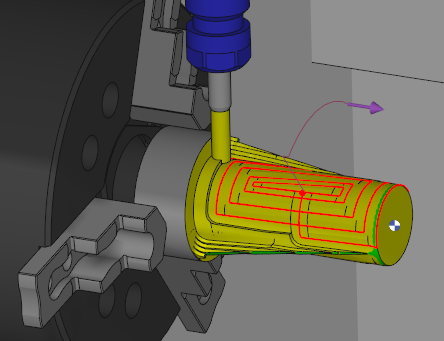

4X roughing standard

| 4 Axis roughing standard is a 4 axis simultaneous roughing operation. |

Key Points

This new operation enable to rough any shape using the 4 axis simultaneously and applying standard offset toolpath. The toolpath starts out of the material in case of open machining area. To avoid a too long calculation time, we advise you to define carefully the mini and maxi diameters of machining, in the strategy page. |  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | Machining direction | Optimization |

Radii on contour | ||

Machining Area | Mini machining radius | Maxi Machining radius |

Definition of Chip | Engagement angle | Respect of scallop |

XY Scallop | Maxi thickness ( h ) | |

Limitation of Machining | Shift of profile | Shift of value |

Starting Distance | Ending Distance | |

Calculation of Z steps | Z Step (Ap) | |

Allowances | XY stock allowances | Normal stock allowances |

Z Stock allowance | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Z plunge | Mini helix rad | Mini ramping rad |

Mini rad mach area | Plunge angle | |

Management of rapids | ||

Safety | XY safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |