Groove Feature

Definition

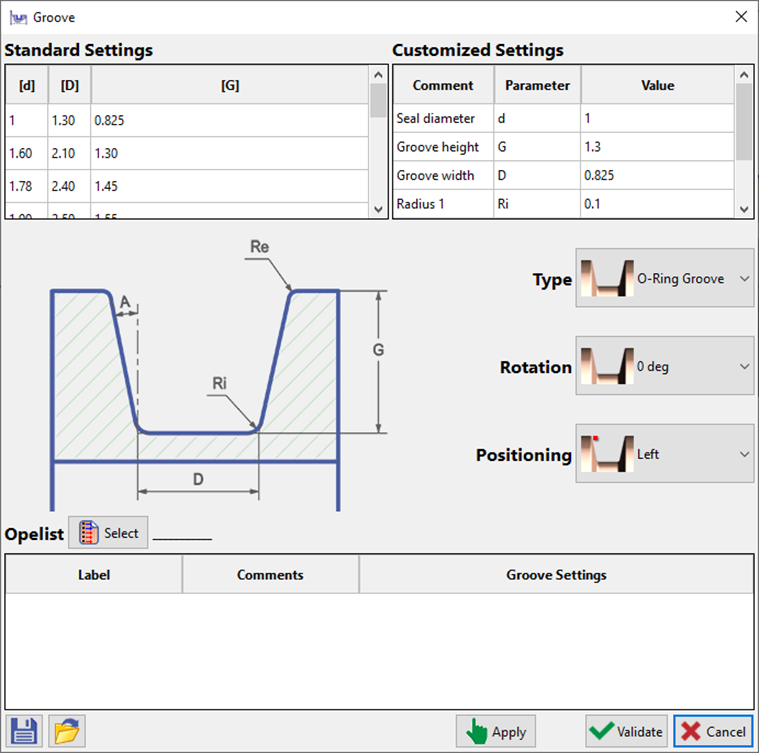

| The Groove feature enables to design standard or customized grooves with assigned opelists. |

Presentation of Dialog

| In the Groove Feature, you can find:

|  |

By incorporating these features, the new command can offer both standard-compliant groove generation and flexibility for customized machining requirements, enhancing user productivity and efficiency | ||

How to work with Opelist ?

Here is the workflow to define an Opelist and use it in the Groove Feature command

Create the Opelist

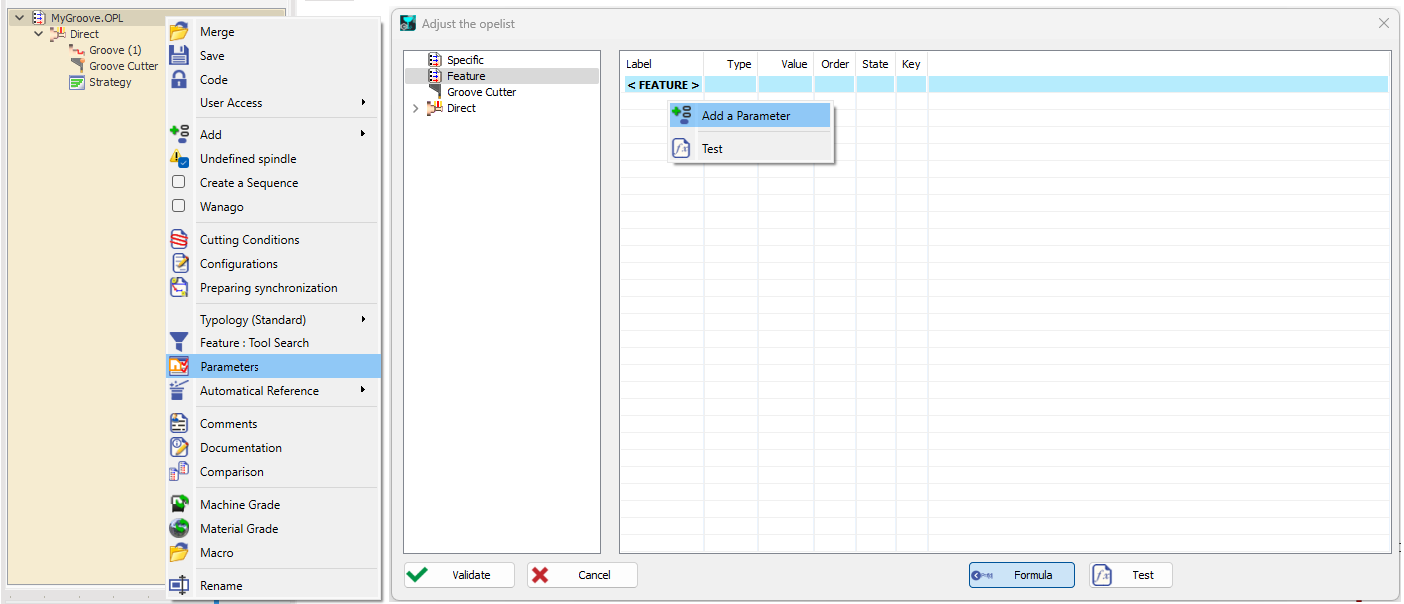

From the Text Menu, use Opelist > Create to create an empty Opelist. Rename it, and use right click to add a Direct Groove operation (Add > Turning > Grooving > Direct)

See Opelists Manager for more details about Opelist creation

Set Opelist parameters

Right click on the Opelist name to access the Opelist parameters.

Click on Formula button to display advanced parameters

Click on Feature to display feature parameters and right click on the parameter list to add a parameter

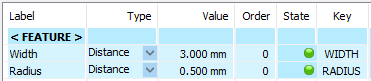

Then add 2 distance parameters, Width and Radius, and set their KEY fields with WIDTH and RADIUS

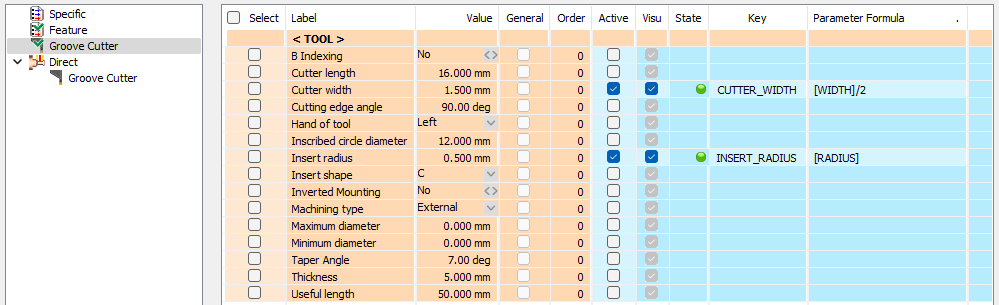

Finally, in the Groove Cutter parameters, link the Cutter width and the Insert radius to the previously created feature parameters

Click on Validate to confirm the parameters and close the dialog window.

Then click on Validate in the Opelist Manager to save your Opelist.

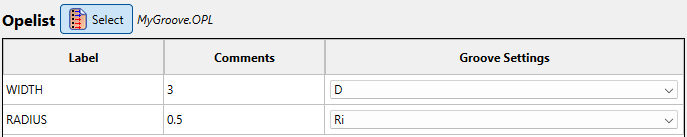

Use the Opelist

Once created, the Opelist is visible in the Groove Feature command and can be selected. Groove parameters can now be link to the Opelist feature parameters WIDTH and RADIUS, in order to set the Cutter width and the Insert radius.

Machining

The groove machining can now be simply added to the machining list by using Turning > Part > 2d Features