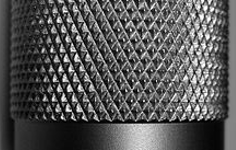

Knurling

| Machining operation that consists in creating combination of horizontal, vertical or crossing lines on the surface of material. The operation is performed for producing indentations on a part of a workpiece. Knurling allows hands or fingers to get a better grip on the knurled object than would be provided by the originally smooth metal surface. |  |

Key Points

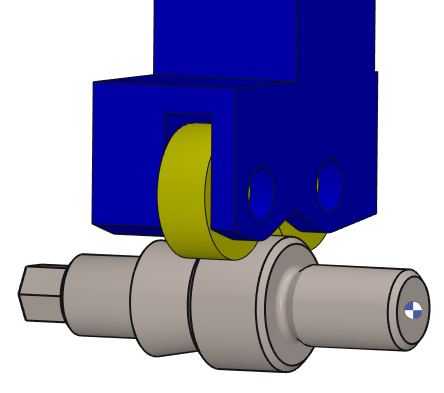

Knurling tools can be one roll or two rolls (as shown in the sample on the right). We can pilot either Left, Center or Right position of the roll. Then 2 types of motions are possible, straight path or by pecking move. |  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Machining Strategy | Machining depth | Lead in distance |

Lead out distance | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | Safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Maxi spindle speed | ||

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

User information | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||