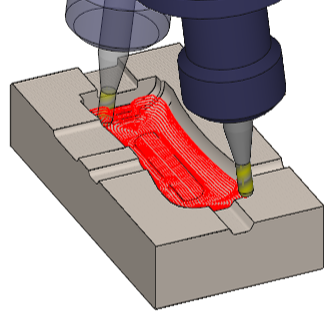

5X Pocket Morphing

| This cycle generates very smooth 5 axes toolpath, by respecting as much as possible the shape of the part. The toolpath is based on the Voronoi mathematical algorithm. This toolpath is especially efficient on cavity shapes and can manage undercut areas. |

Key Points

|  |

If you do not define a Drive Profile, the calculation is based on the bounding box of the whole shape!

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | Machining direction | Machining Method |

Path direction | ||

Definition of Machining Area | Machining Area/Reference | Offset type |

Offset on drive profile | ||

Stepover Calculation | Stepover (Tool ratio) | Stepover value (Ae) |

XY Scallop | ||

Allowances | XY Stock allowance | Z Stock allowance |

Normal stock allowance | ||

5 Axes Machining | ||

Maxi Distance Undercut |

| |

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Approach and return in Z | Retract altitude | |

Leadin and leadout in XY | Lead in length | Lead out length |

Lead in arc radius | Lead out arc radius | |

Leadin radius angle | Leadout radius angle | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |