Profile

Introduction

This method represents a special case in which a pocket is created from the edges of the solid rather than from a face, as in other cases. It is designed to address two specific situations: a shape without a bottom face or a shape with a non-flat bottom face.

Characteristics

The displayed profile must be closed; an open “profile” pocket cannot be created.

Warning: Undercut shapes are not supported. The created profile should be verified before programming the cycle.

Advice:

This type of profile is intended for shapes where a flat face cannot be selected.

The two main cases are:

a pocket through material

a pocket with the bottom face which is not flat.

Methodology

Right-click to select Profile

Click a flat face.

Click one edge of the area to machine.

Give the Bottom Z of the pocket

Examples

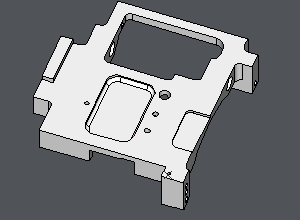

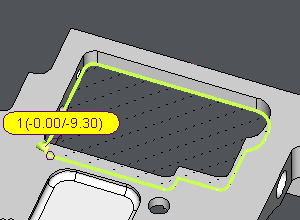

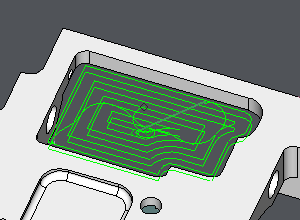

Pocket through material First, the flat face containing the edge is selected. Next, an edge of the pocket to be machined is indicated. The bottom Z value is then specified by selecting the bottom of the wall, which is at Z-9.3. The profile is created at this altitude, though it can be adjusted in the dialogue box if desired. In this instance, the pocket could be machined from the two opposite sides; alternatively, the bottom altitude could be modified to machine through in a single pass. |  |

|  |

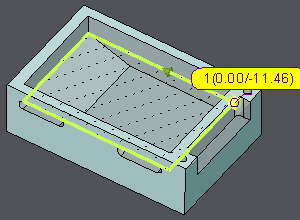

Pocket with a non-flat bottom face First, the flat face containing the edge is selected (in this case, the top face). Next, an edge of the required pocket is indicated. The bottom Z value is then specified by selecting the altitude where the slope begins. This configuration allows a roughing pass of the pocket to be performed without including the slope face. |  |