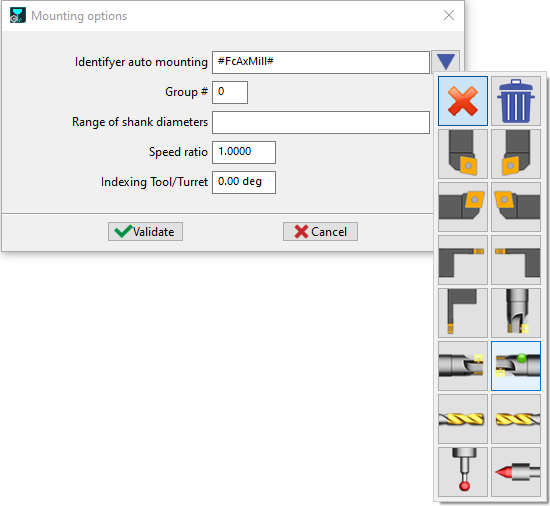

Auto Mounting

| The auto mounting system in GO2cam intelligently manages the placement of tools on both the spindle and turret, streamlining setup and optimizing machining efficiency. |

How It Works:

Rules for Auto-Mounting Tools Based on Diameter Range and Tool Family

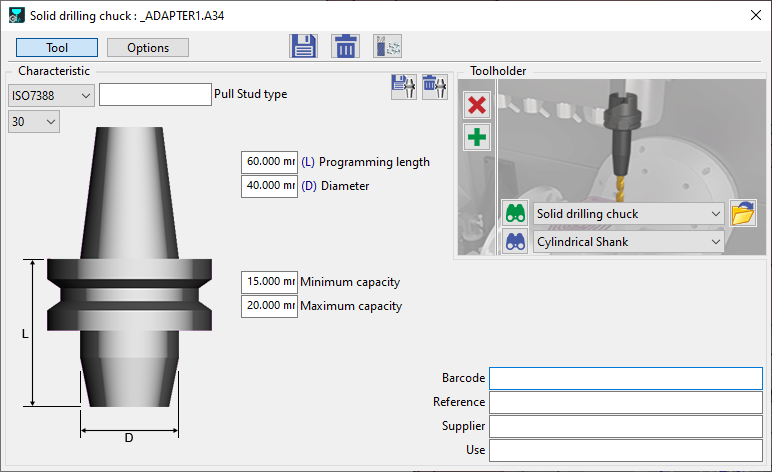

Tool Mounting in Swiss Machining – Useful Length Selection

A tool group can be configured with a maximum useful length parameter. Additionally, each individual tool may define its own maximum useful length.

During automatic mounting or manual drag-and-drop mounting operations, the system determines the applicable useful length by referencing a designated tool. If no reference tool is specified, the machine's default useful length setting is applied.