Tooling Menu

Introduction

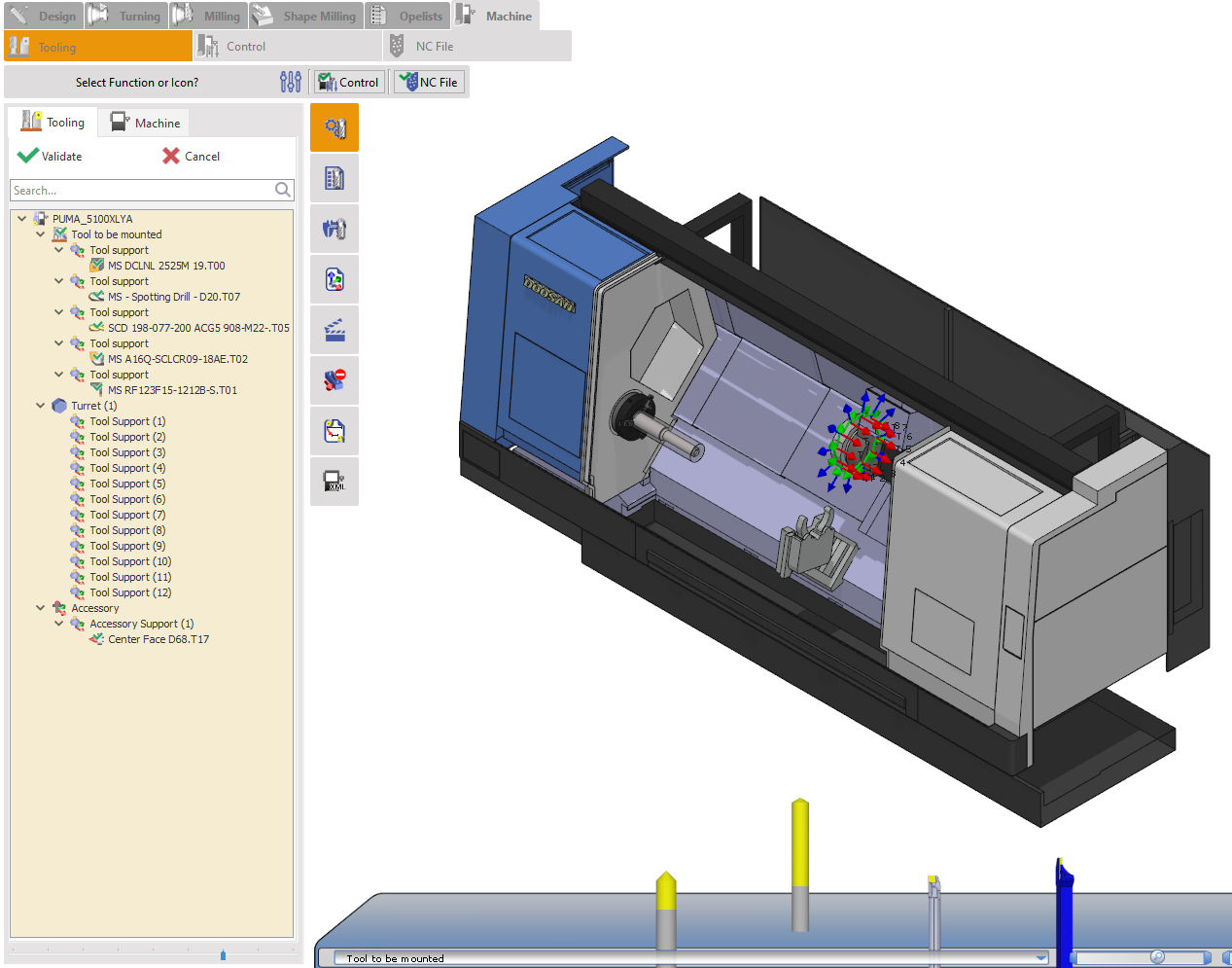

| This menu is used to configure the machine environment in order to enable machining simulation. When you click on the Tooling menu, the user will be prompted to set up the tool. |

The Tool Tree displays all tools required for the machining process. Under “Tool to be mounted”, you will find tools that are currently unmounted. Under “Magazine Spindle/ Turret”, you will see the machine’s tool magazine, which lists tools that are already mounted. To mount a tool, drag and drop it from its Tool Support location to the appropriate Pocket in the magazine. Insert a tool holder for each of the tools if they haven’t yet been defined. The Machine sub-tab shows the setup of the machine. The selected pocket must correspond to the actual pocket on the physical machine to ensure the tool number matches the one used in the NC program. |  |

Tooling User Interface & Manipulations

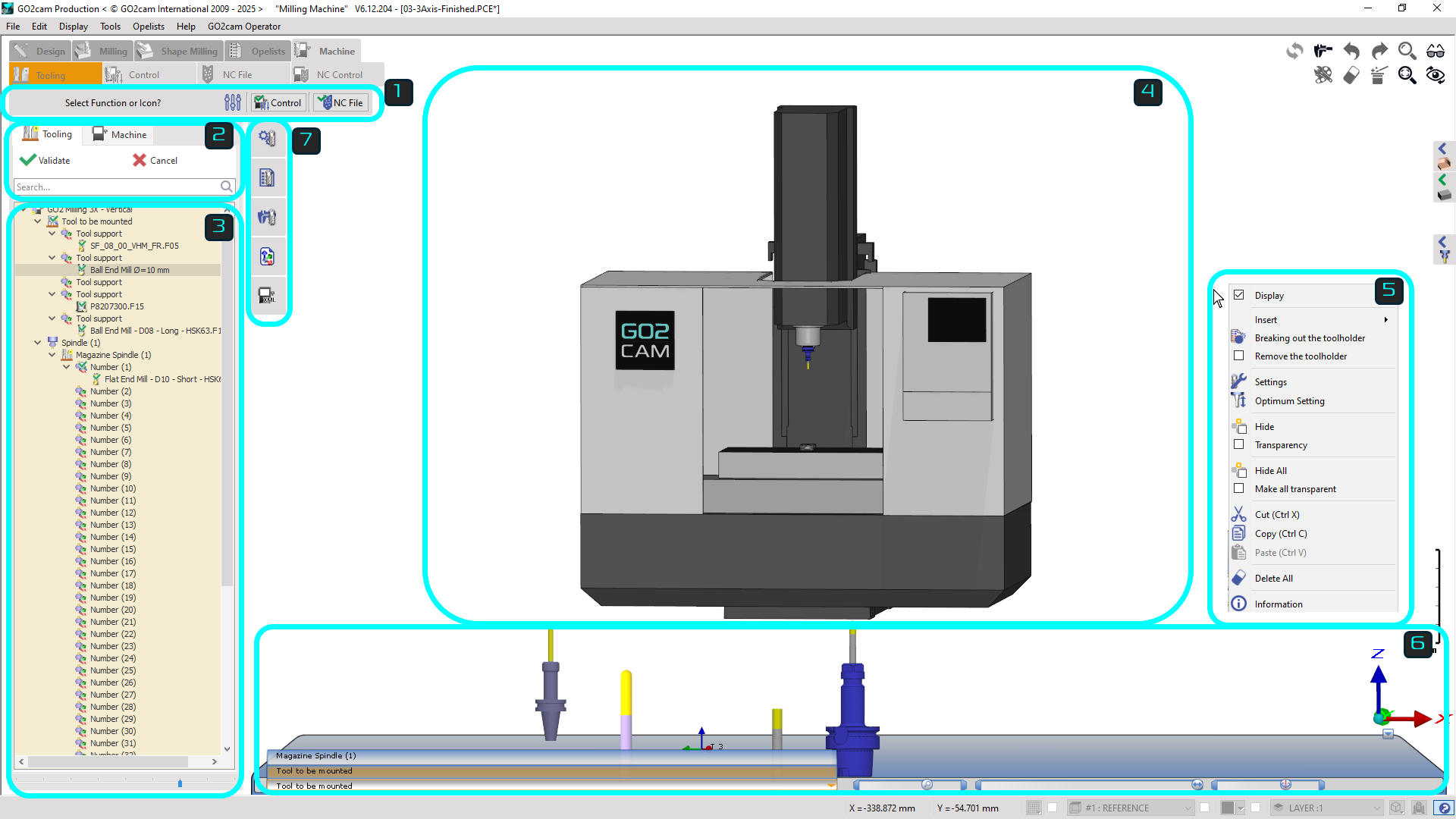

| ||

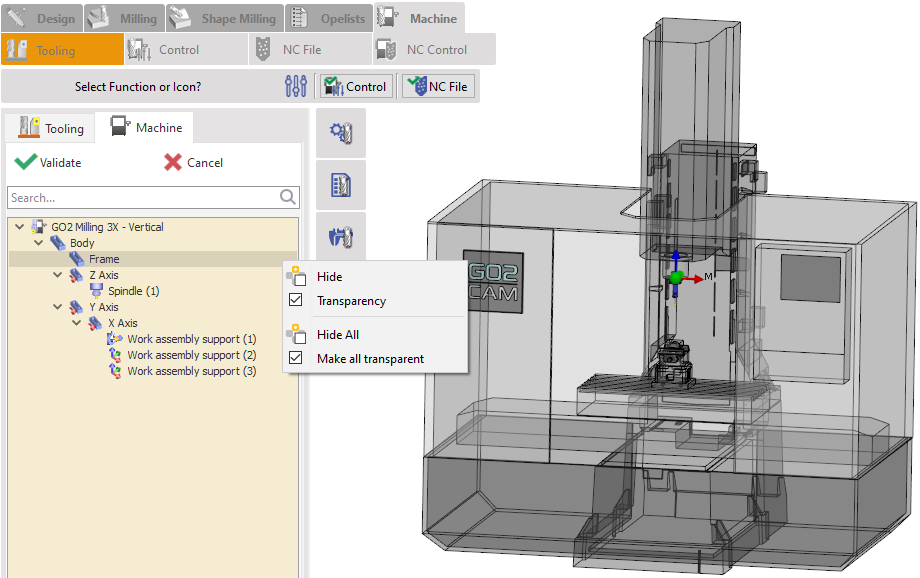

| Ribbon: Provides settings for the graphics display, collision detection, validate and move to the control menu and validate and call the post-processor | |

| Tooling tree tab: Two tabs are present; the main Tooling tab for all the settings of the tool on the machine and the Machine tab for display functions of the machine components. | |

| Tooling tree: The tree lists all the tool mounting axes on the machine. It is segregated into the list of tools to be mounted and the racks/turrets/spindles on which the tools can be mounted. | |

| Graphics window: The 3D model of the machine and its components and tool mounting axes that can be interacted with and manually mount tools and toolholders. This provides a visual understanding of the settings. | |

| Pop-up menus: Various pop-up menus are available with different functions for each sections, such as the tree, tool/toolholder, machine window, etc. | |

| Tool rack: The 3D models of the list of tools to be mounted or already mounted are shown on the rack at the bottom. The user can drag and drop the tools from there to the machine, add toolholders, etc. | |

| Toolbar Commands: This menu provides advanced settings for the tooling and machining process. | |

Watch a video describing the the interface and their functions. |  | |

Tool Mounting Methods

There are multiple ways to manually mount tool in MTE:

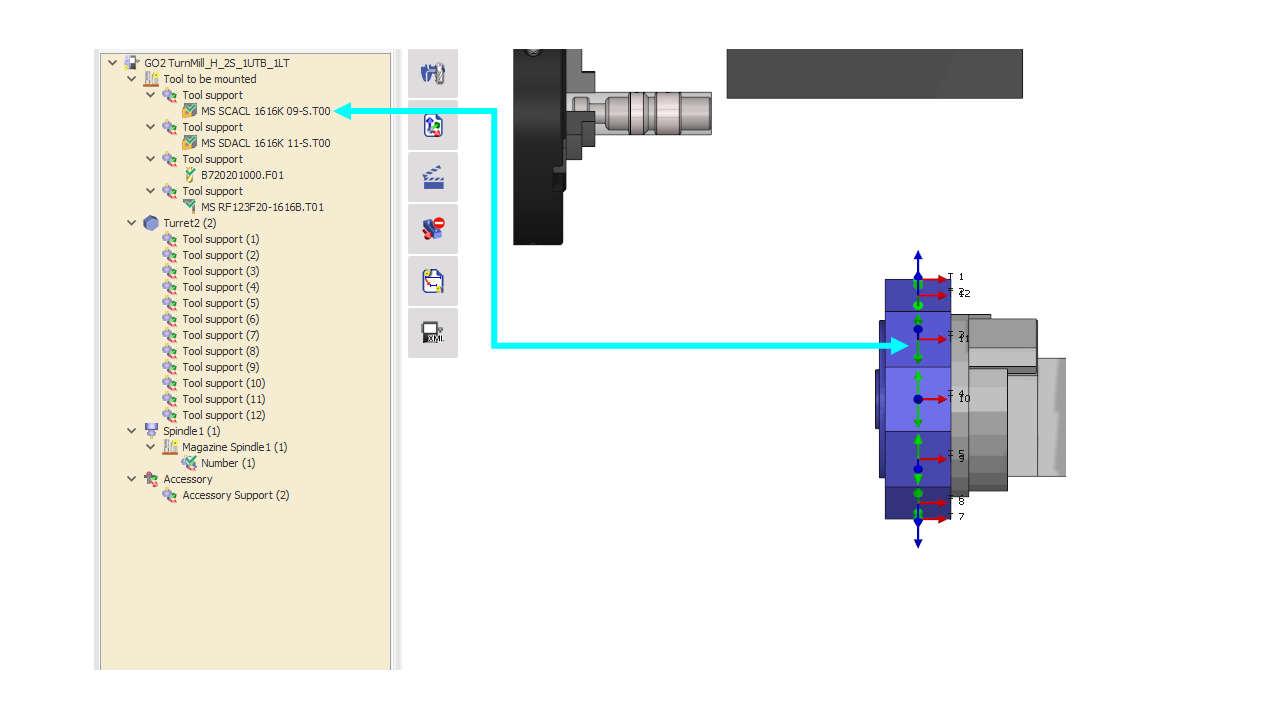

Using the Drag & Drop in the Tooling Tree

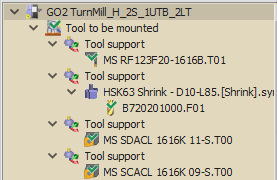

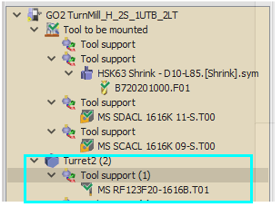

In the tooling menu, you’ll find a section labeled ‘Tool to be Mounted’. Each tool support in this section contains a tool that needs to be mounted. To manually mount a tool, simply drag and drop it from the ‘Tool to be Mounted’ section to an available tool support on your turret or spindle. Example:

| |

Image 1 |  Image 2 |

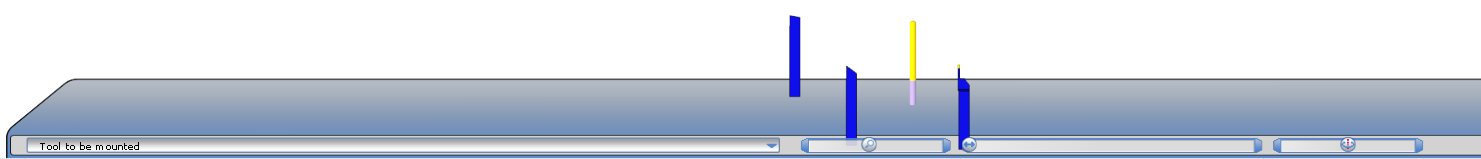

Drag & Drop of 3D tool from Rack to Turret/Spindle

In the MTE Tooling Interface, you’ll find a rack at the bottom(shown in Image 3) containing tools ready for mounting. To manually mount a tool, simply drag and drop the 3D model onto the desired turret or spindle tool support, each of which is labeled with a numbered axis system for easy identification. |

Image 3 |

Drag & Drop from Tooling Tree to Turret/spindle.

Pop-up menus

Below find the parameters you obtain from the popup menus of each different section:

Machine pop-up

| New | This option removes all tools currently mounted on the spindle or turret, allowing you to start fresh with a new tool setup. |

| Open | Open existing FMO file |

| Save as… | Save all tool configuration on the machine as an FMO file |

| Assign tools of machine | Automatically replace tools defined in the cycles with compatible tools already mounted on the machine(as FMO file). Click on the link for details. |

| Tool List | Open list of tool |

| Delete all the toolholders | Remove all solid toolholders on the machine |

| Delete all | Remove every tool and toolholders mounted on the machine |

Tool to be Mounted pop-up

Display | To hide/show the tool rack | |

| Centre-to-Centre | To adjust spacing between tools on the tool rack. |

Tool Support pop-up

Insert | Allow you to add a solid or standard toolholder | ||

| Hide | Hide/Unhide the tool and toolholder attached in the selected tool support in the 3D environment | |

Transparency | Make selected component transparent in the 3D environment | ||

| Hide all | Hide selected group of component in the 3D environment | |

Make all transparent | Make selected group of component in the 3D environment transparent | ||

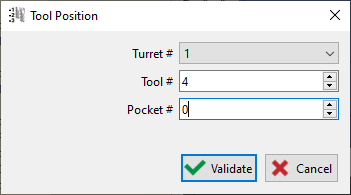

| Change position | Allow to move the components of the current tool support to another tool mounting position in the machine. This can be to another turret or rack, another tool support position on the turret or even another pocket position in the same tool support if available. |  |

| Cut | Removes the components from the selected tool support(maintained in the clipboard) that can be pasted to another tool support position. | |

| Copy | Creates a duplicate of the selected tool on the clipboard | |

| Paste | Inserts the tool from the clipboard | |