List of tools

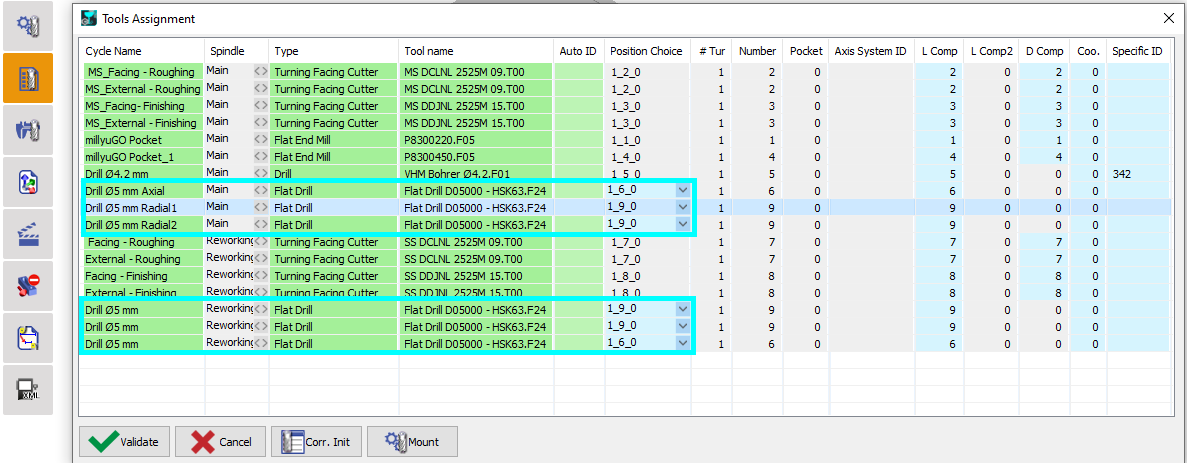

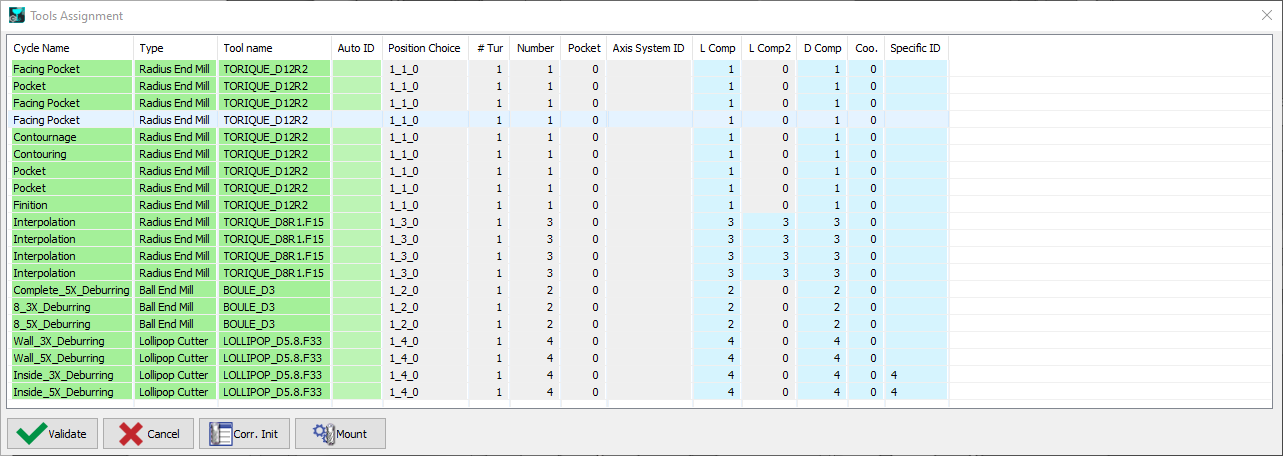

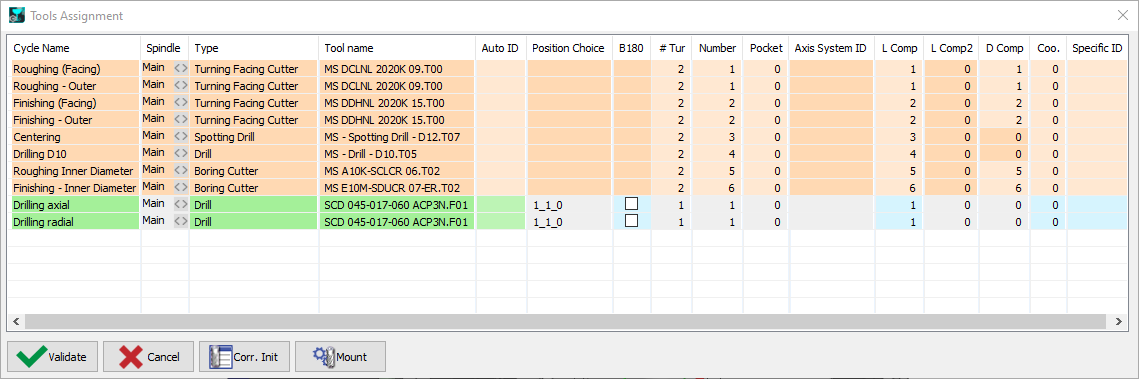

| The Tools List allows you to manage tool-specific settings, such as radius compensation and coolant supply. This feature is used for:

|

Tools List in Milling |  Tools List in Turning |

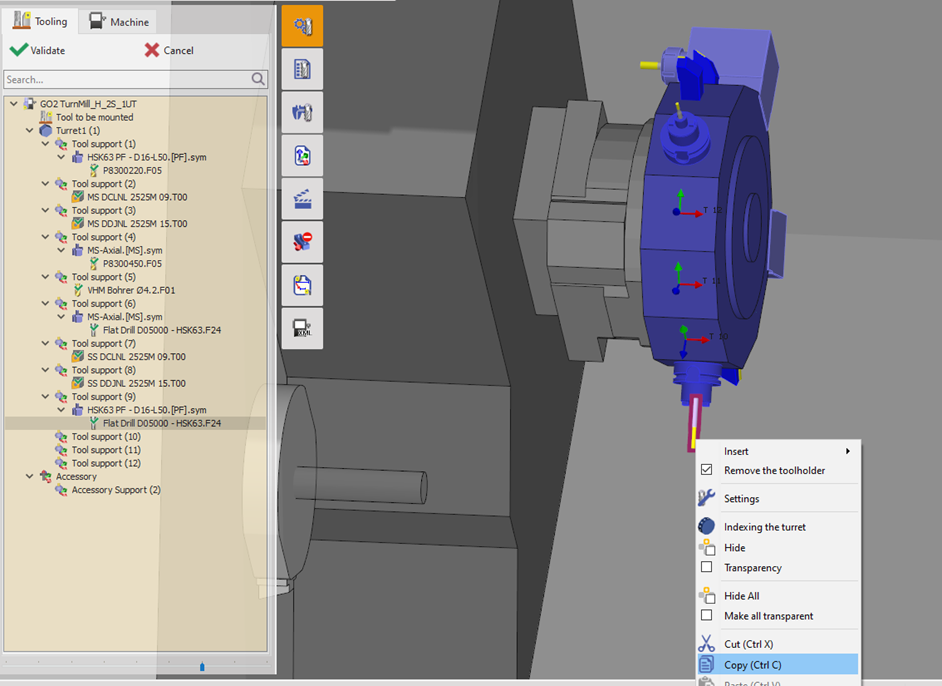

To manually mount tools:

Note: For tools used in multiple operations, modifying settings in the first occurrence will automatically update subsequent instances. An automatic assembly function is available, but it doesn't consider MTE factors. | |