Gauge of tools

| A tool gauge is a set of measurements that define a tool's exact position and orientation relative to the machine. These measurements include the tool's length, offsets in X, Y, and Z directions, and any necessary angular adjustments. Accurate tool gauges are crucial for achieving precise machining results. |

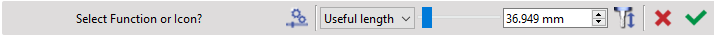

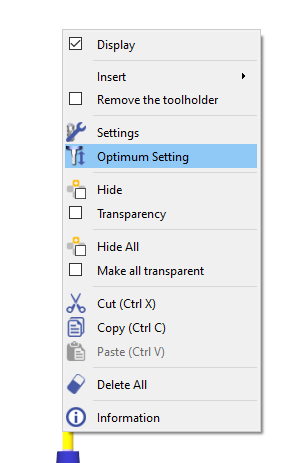

To optimize a tool's position relative to its toolholder:

This process can also be applied to toolholders and tools already mounted on the spindle.

|

|

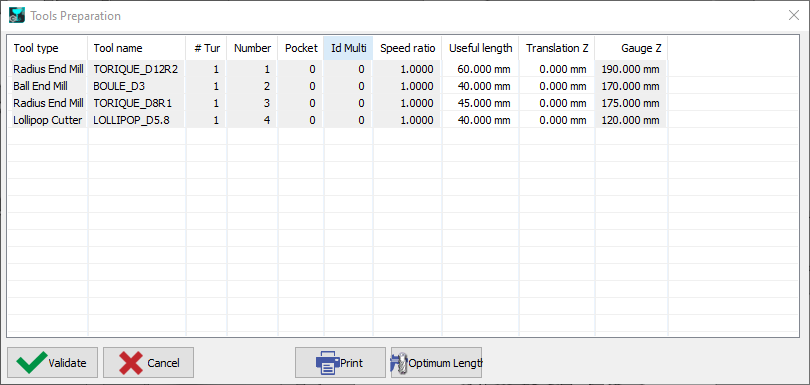

Using Gauge of Tools menu: Once tools are installed on their respective stations, fine-tune their settings:

| |

Tools Preparation | |