Scenario

| GO2cam's scenario-based machining allows you to dynamically reorder machining sequences to test alternate production strategies, without modifying the original program database. This provides the flexibility to explore different scheduling approaches, evaluate machining time, and revert to previous configurations at any point. |

Process Flow

The system clones tools across turrets, enabling dynamic resource allocation and flexible positioning during machining cycles. This allows the software to simulate and optimize various process flows while keeping tool usage synchronized across channels. For each scenario, the system:

This method combines intelligent computation with visual control, enabling users to refine their machining strategies with immediate feedback. |

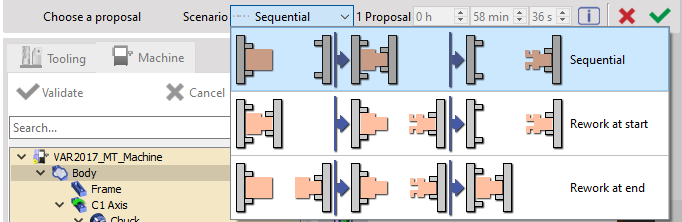

Operational Modes

Three distinct scenarios (or modes) are available. Each represents a different approach to organizing machining steps between the main and rework spindles: Sequential Mode Main spindle machining → Parting and transfer to rework spindle → Rework spindle finishing This is the traditional sequence where all machining is completed on the main spindle before transferring the part. Rework at Start Initial parting and transfer to rework spindle → Simultaneous machining on both main and rework spindles Useful for accelerating production by starting both spindles earlier in parallel. Rework at End Concurrent main and rework spindle operations → Final parting and transfer to rework spindle This scenario delays parting and transfer until the end, maximizing main spindle activity upfront. |