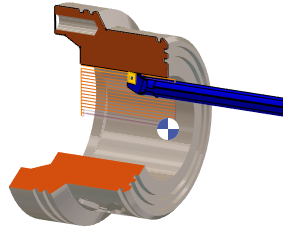

Drilling reaming

| This cycle is a drilling operation programmed with a reaming tool. |

Key Points

The purpose is to have one only tool for the drilling and the roughing and consequently, one tool number in the machine.

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Extra Options | ||

Machining Strategy | Drilling | Drilling Depth |

Lead out distance | Pass Depth | |

Last pass depth | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | Safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Spindle speed |

Cutting speed | Feedrate in Z | |

Speed range | Spindle direction | |

Feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

User information | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||