Geometry Selection

The selection of geometry to program operations is a complex topic.

Almost each machining menu has his own method and characteristics. It also depends on the type of geometry, wireframe or solid.

Many information can be found here:

Direction Of Profiles and Toolpaths

In general:

For milling, the G17 ( Z+ Plane) is the default setting. It defines the working plane where the X and Y axes determine the toolpath. Imagine a flat surface where the machine moves the cutting tool across the length (X) and width (Y).

For turning the G18 (Y+ Plane) is the default setting. Here, the toolpath is defined by the X and Z axes. In simpler terms, the tool moves along the length (X) and depth (Z) of the material.

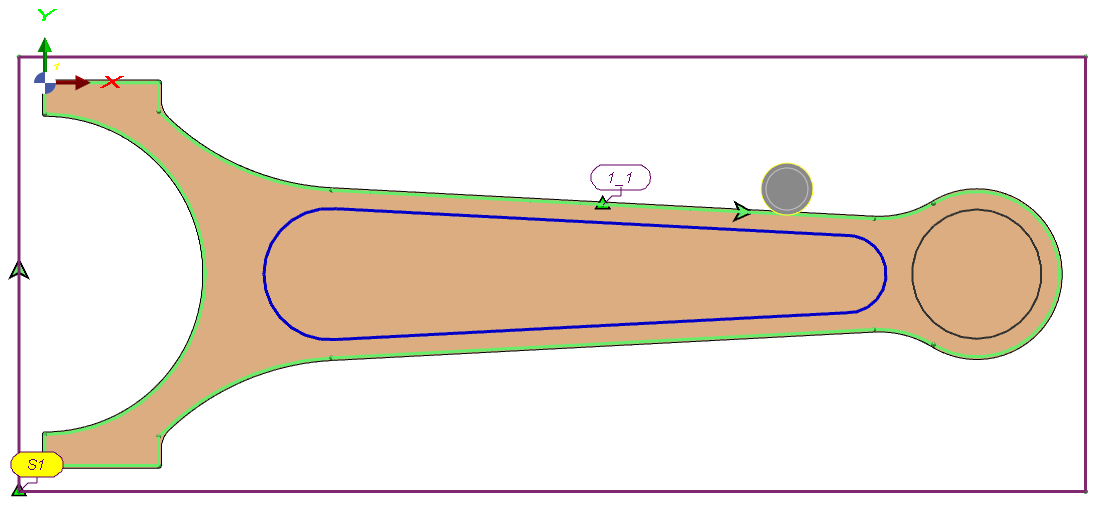

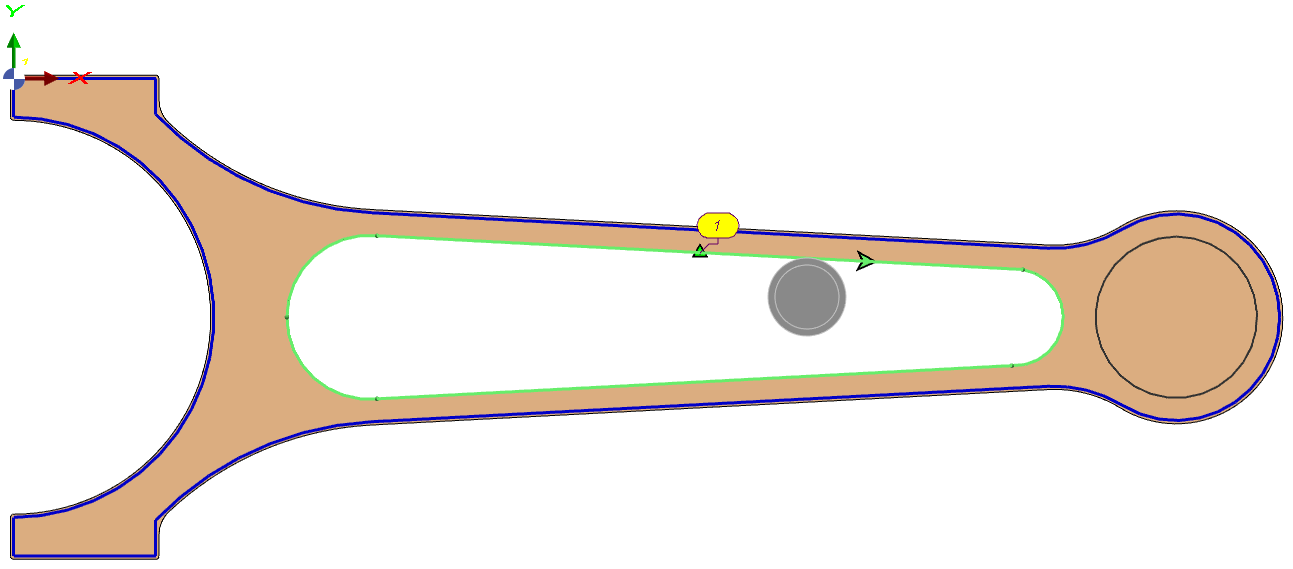

The direction of the profile selected determines the position of the toolpath (Right/Left). See an example on a milling part below:

The tool is on the left of the profile ( Clockwise) for an open pocket |  The tool is on the right on the profile (Clockwise) for an inner pocket |