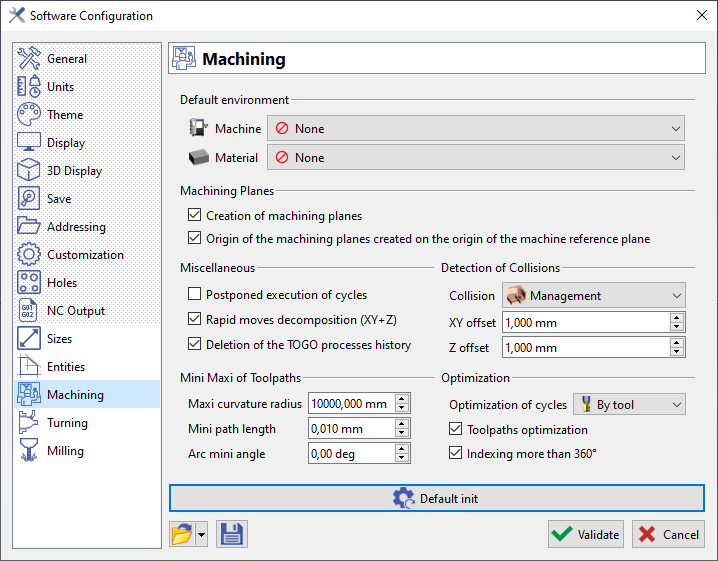

Machining

Definition

Many options regarding machining environement, toolpaths calculation and management of collisions.

6 sections are given:

|  |

Default Environment

Machine: choose a machine file that will be loaded automatically when starting the software.

Material: same for a material file.

Machining Planes

Creation of machining planes: if this option is checked, if ever a plane other than reference is selected, a machining plane for that specific plane will be created and shown in the Toolbar.

Origin of the mahcining planes created on the origin of the machine reference plane: the origin of the machining is always set in the reference plan, if this option is checked

Miscellaneous

Postponed execution of cycles: create cycles without calculating the toolpath (3D machining)

Rapid moves decomposition (XY+Z): rapid movements calculation in XY then Z or XYZ.

Deletion of the TOGO processes history: impossible to edit the process (but the unitary cycles).

Detection of Collisions

The 3 parameters regarding the management of collisions are common to all the machining cycles in the software: here we define the default settings that will appear in each machining cycle.

Mini Maxi of Toolpaths

Maxi curvature radius: maxi arc available during the decomposition of a curve into an arc.

Mini path length: define the mini length of toolpath supported by your machine.

Arc mini angle: mini angle (degrees) to change an arc into a segment on Part Toolpath.

Optimization

Optimization of cycles: the choice done here will be the default settings in the command optimization.

Toolpath optimization:

Indexing more than 360°: used for continuous operations.