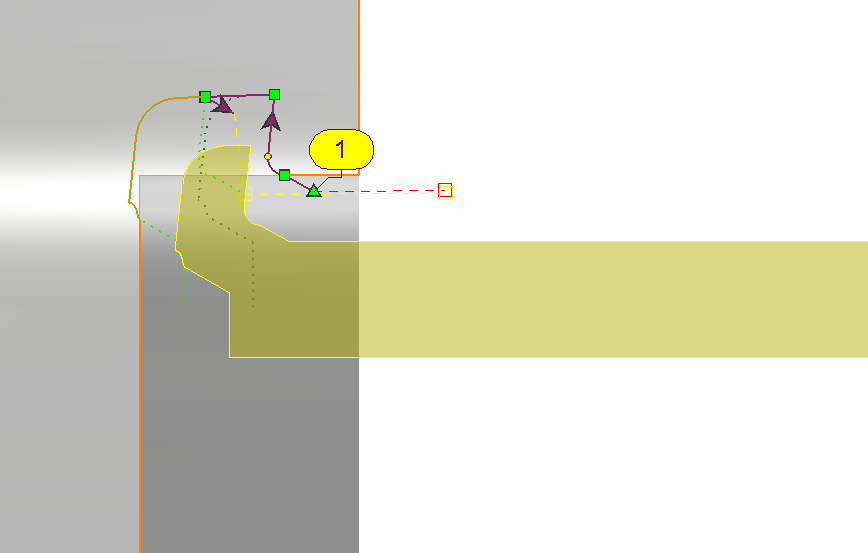

Point to Point

| This is a very specific toolpath since it follows any geometry with standard turning tool and specific forming tools. One pass is calculated, but be very careful: there is no gouge checking on this cycle! Also, there is no removal material on the stock! |

Key Points

The toolpath is determined manually, just following the selected geometry with G01 and G02/03 motions. The approach and return points are set in the geometry selection. These points control where the cutting tool starts and ends its movement relative to the workpiece.

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | Cycle type | |

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | Safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Maxi spindle speed | ||

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

User information | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||

Curves Computing | Curve Tolerance | Curve explode into |