PP - M67 Fagor

The standard has three configuration pages to manage all options available: The first page “CNC Controller” is about CNC options. The second page “Milling” allows to adapt the output for Milling, tools, coolant and origins. The third page “Milling” is about 5 axis parameters. |

CNC Controller page

CNC Generation

Option | Result | |

Until 8055 | Some outputs are done to respect the programming of Fagor 8050 and 8055. | |

After 8055 | Some outputs are done to respect the programming of Fagor 8060 and after. |

For example the output of, program start, canned cycle and tilted work plane are not the same.

Tool Offset

For the option “D..” the tool offset is read in the technology page of cycle

Option | Result | |

D1 | ….T01 D01 … …T10 D01… | |

D.. | …T01 D01… …T10 D10… |

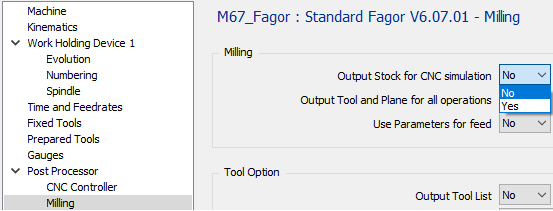

Milling page

Milling Section

Output Stock for CNC Simulation

There is no output for this option for Fagor post-processor

Option | Result |  |

No | %1000 … | |

Yes | %1000 … |

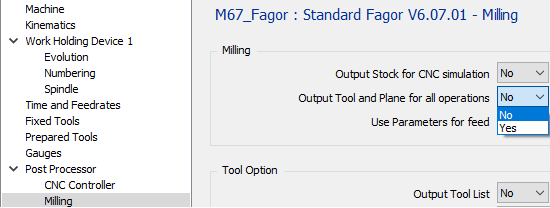

Output Tool and Plane for all operations

Option | Result |  |

No | ;OP 1 WITH TOOL 1 AND PLANE 1 T01 M06 G49 X.. Y.. Z.. Q.. R.. Q.. … ;OP 2 WITH TOOL 1 AND PLANE 1 … | |

Yes | ;OP 1 WITH TOOL 1 AND PLANE 1 T01 M06 G49 X.. Y.. Z.. Q.. R.. Q.. … ;OP 2 WITH TOOL 1 AND PLANE 1 T01 M06 G49 X.. Y.. Z.. Q.. R.. S.. … |

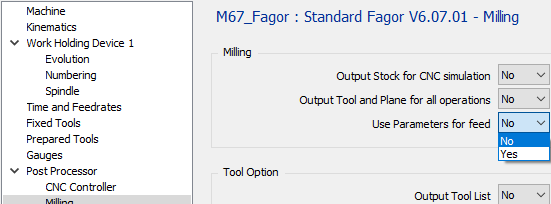

Use Parameters for Feed

Option | Result |  |

No | T1 M6 G00 X.. Y.. G43 H1 Z.. Z-.. F160 G1 X.. Y.. F200 … | |

Yes | P1 = 200 P2 = 160 T01 M06 G0 X.. Y.. G43 H1 Z.. Z-.. FP2 G1 X.. Y.. FP1 … |

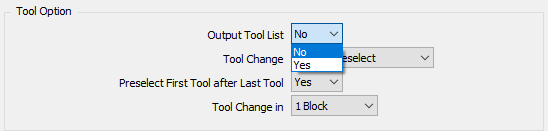

Tool Option Section

Output Tool List

Option | Result |  |

No | % O1000 … | |

Yes | % O1000 ;START TOOL LIST ;T01 END MILL D10 ;T02 DRILL D08 … ;END TOOL LIST … |

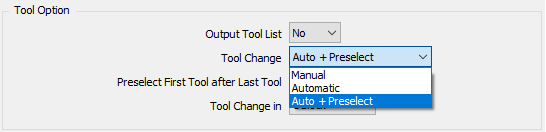

Tool Change

Option | Result |  |

Manual | … M00 … | |

Automatic | … T01 M06 … | |

Auto + Preselect | … T01 M06 T02 … |

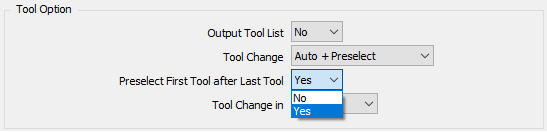

Preselect First Tool after Last Tool

Option | Result |  |

No | ;FIRST OPERATION T01 M06 T02 … ;LAST OPERATION T05 M06 … M30 | |

Yes | ;FIRST OPERATION T01 M06 T02 … ;LAST OPERATION T05 M06 T01 … M30 |

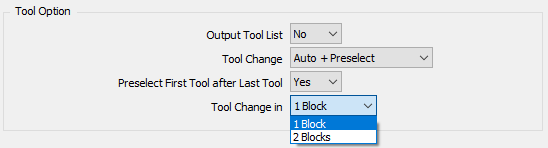

Tool Change in

Option | Result |  |

1 Block | … T01 M06 … | |

2 Blocks | … T05 M06 … |

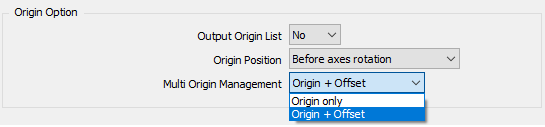

Origin Option Section

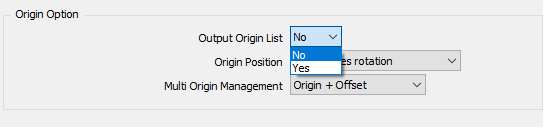

Output Origin List

Option | Result |  |

No | % O1000 … | |

Yes | % O1000 ;START ORIGIN LIST ;G54 ;G55 ;END ORIGIN LIST … |

Origin position

Option | Result |

After axes Rotation | … G49 X0. Y0. Z0. Q0 R0. S0 G54 |

Before Axes rotation | G54 … G49 X0. Y0. Z0. Q0 R0. S0 |

Multi Origin Management

Option | Result |  |

Origin Only | % O1000 … G54 … | |

Origin + Offset | % O1000 … G54 G158 X10 Y20 Z10 … |

Without MTE :

If the option is set to “Origin Only” for each origin define on the part, we will output a different G code, G54, then G55, G56 … It means you are limited by the number of origin managed by the CNC. If you can have more origin, you must use the second option “Origin + Offset”

If the option is set to “Origin + Offset” it will only output G54 and offset with G158

The G158 function is only available for CNC start 8060 generation.

With MTE :

The origin can be define in the name of the origin with the following syntax “$G54_”. It means G54 will be used in the NC program. If there is no decoded name define, it will output the default origin G54.

If you use “Origin + Offset”, you must use only one origin for all your operation because all the offset are compute from the reference plane origin or single origin.

You can add every text after the underscore to recognized your offset “$G54_Up”, “$G54_Right”, …

With 5 axis machine :

The origin offset is output with the tilted plane function G49 or #CS if is set to be output. So it means no G158 is output.

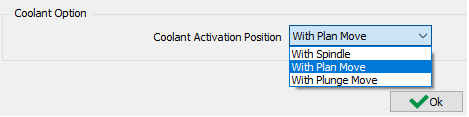

Coolant Option Section

Coolant Activation Position

Option | Result |  |

With Spindle | … T01 M06 S8000 M03 M08 G00 X.. Y.. G43 H1 Z… … | |

With Plane Move | … T01 M06 S8000 M03 G00 X.. Y.. M08 G43 H1 Z.. … | |

With Plunge Move | … T01 M06 S8000 M03 G00 X.. Y.. G43 H1 Z.. M08 … |

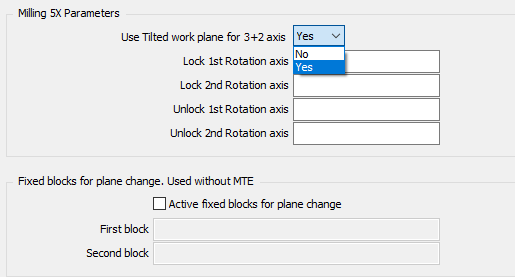

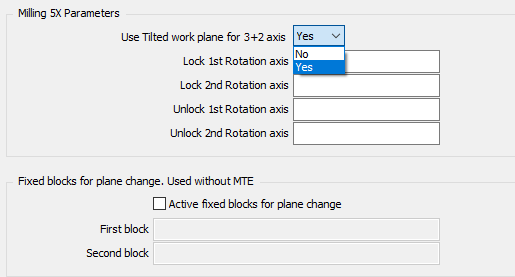

Milling 5X page

Milling 5X Parameters

Use Tilted work Plane for 3+2 Axis

The tilted work plane is output with Euler angle by default. For Fagor CNC, the Euler angle are done for rotation around Z then Y then Z.

Option | Result Until 8055 | Result After 8055 |  |

No | … T01 M06 C180 A-90 … | ||

Yes | … T01 M06 G49 X.. Y.. Z.. Q-90 R180 S0 … | … T01 M06 #CS NEW[1][MODE 2,-90,180,0] #TOOL ORI … | |

Rotation Axis

| |||

Option | Result | Option | Result |

Lock 1st Rotation Axis | Lock 2nd Rotation Axis | ||

empty | … C180 … | empty | … B-90 … |

“M10” | … C180 M10 … | “M12” | … B-90 M12 … |

Unlock 1st Rotation Axis | Unlock 2nd Rotation Axis | ||

empty | … C180 … | empty | … B-90 … |

“M11” | … M11 C180 … | “M13” | … M13 B-90 … |

Fixed blocks for plane change (Used without MTE)

Active fixed blocks for plane change

This option is used only if there is no kinemac defined in the machine configuration.

Option | Result |

check | The fixed blocks defined will be output if there is a plane change |

uncheck | No block will be output if there is a plane change. |

First and Second Block

Option | Result |

Empty | … … |

“G0 Z100” | … G00 Z100 … |

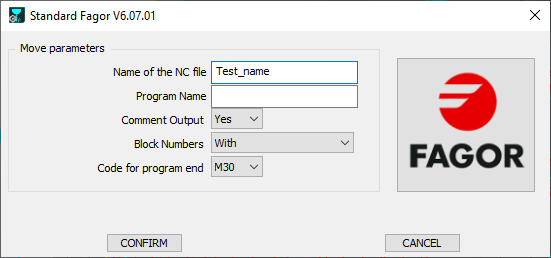

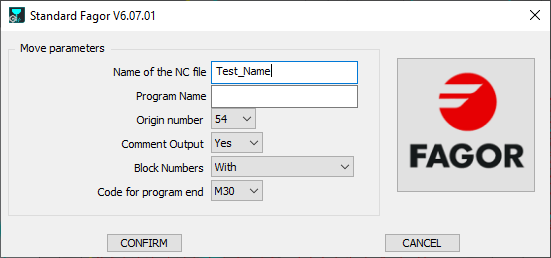

Launch page

With machine kinematic defined | Without machine kinematic defined |

|  |

Name of the NC File

Define here the Name of the generated NC file. The extension must to be defined in the MCF configuration.

Program Number

If empty text is defined, the program Name will be set to 1.

Option | Result Until 8055 | Result After 8055 |

empty | %1, MX, … | %1 … |

“PROG1” | %PROG1, MX, … | %PROG1 … |

Origin Number

This parameter is use only if kinematic is not defined in the machine file. The parameter defines the first origin used in the NC program.

If the parameter to treat multi origin is set on “Origin Only” the origin number is incremented when a plane changes.

Option | Result Until 8055 |

54 | %1, MX, T01 M06 G54 … |

55 | %1, MX, T01 M06 G55 … |

Comment Output

Option | Result |

No | … T01 M06 … |

Yes | … ;FACING ;END MILL D12 T01 M06 … |

Block Numbers

Option | Result |

With | O1000 N5 T01 M06 N10 G00 X.. Y.. N15 G43 Z.. H1 … N50 T02 M6 N55 G00 X.. Y.. N60 G43 Z.. H2 … |

Without | O1000 T01 M06 G00 X.. Y.. G43 Z.. H1 … T02 M06 G00 X.. Y.. G43 Z.. H2 … |

Tool Change Only | O1000 N5 T01 M06 G00 X.. Y.. G43 Z.. H1 … N10 T02 M06 G00 X.. Y.. G43 Z.. H2 … |

Code for Program End

Option | Result |

M30 | … M30 % |

M02 | … M02 % |