Probing

Introduction

GO2cam provides probing cycles to automatically measure and locate the position of a workpiece or verify part dimensions on the CNC machine itself. The main purposes of probing are:

|  |

Benefits:

| |

Probing Cycles

The various types of probing functionalities provided in the software are:

| 1 | Tool Probe (Tool Setting - Tool Break) Objectives:

|

There is no operation or cycle to define the tool probe in GO2cam because this operation is part of the tool change on the machine. This is managed in the Post Processor where the NC code to generate the probe action is called in the tool change procedure and the machine manages the operation. Simulation of the tool probe can be programmed in MTE via the Post Processor. |

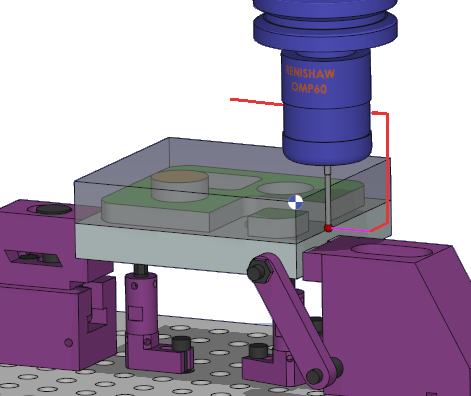

| 2 | Stock positioning on the machine

| |

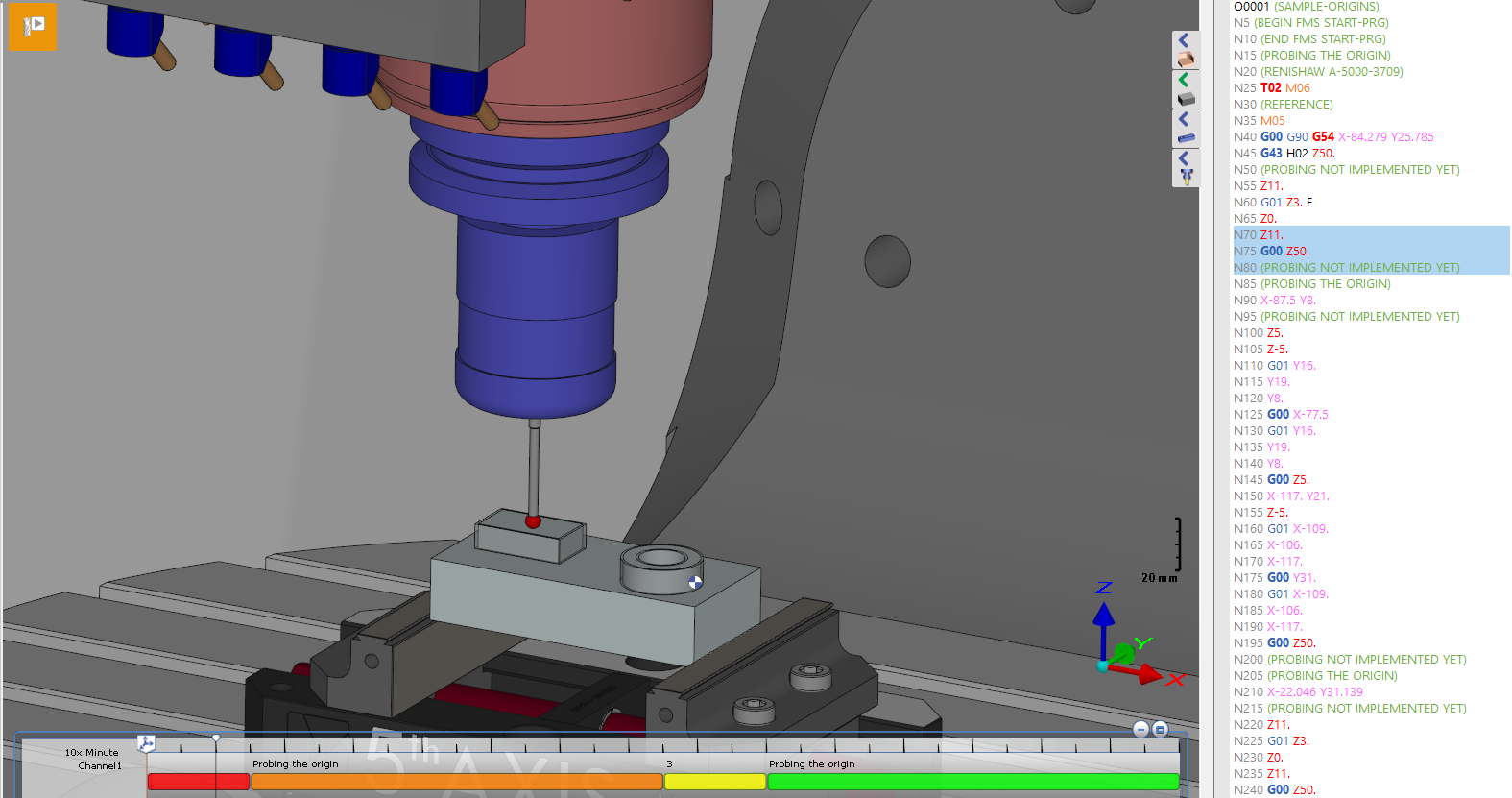

| 3 | Stock probing to define origins

| |

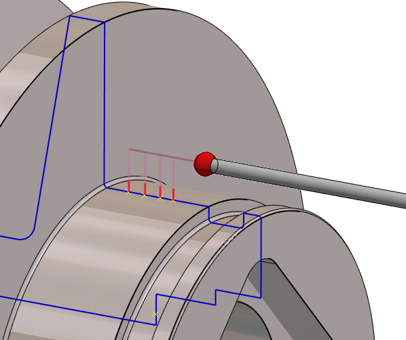

| 4 | In-process Probing during machining

| |

| 5 | Finish part Measuring / Quality Control

| |

Wireframe geometry can also be selected to enforce specific points for probing. The point is then automatically projected onto the solid according to the nearest normal direction.

If the coordinates of a probed point are modified (SHIFT + left-click), the new coordinates are automatically projected onto the solid.

The advantage of using wireframe geometry lies in the ability to utilise the silhouette positioned at Y = 0 for turning operations.