Alignment of Part

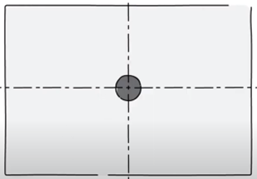

Definition

| This operation, done on the stock, enables the fixing of issues of part positioning. When the part is clamped, we check the alignment of the part; if it is not correct, two options are possible to re-align the part:

|

Misalignment of a very simple part without probing | ||

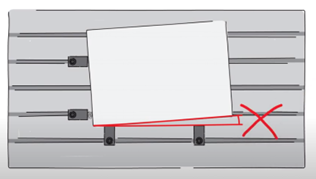

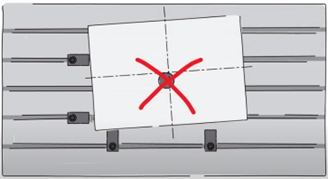

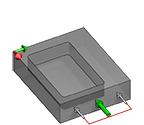

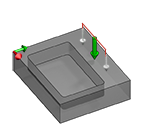

A hole needs to be drilled at the center of the cuboid. |  On clamping the part, it is not properly aligned. This misalignment may not be visible but contributes in the inaccuracy of the operation. |  Without probing, the hole drilled is off-center and this may not be tolerable for precision parts. |

Misalignment correction with probing | ||

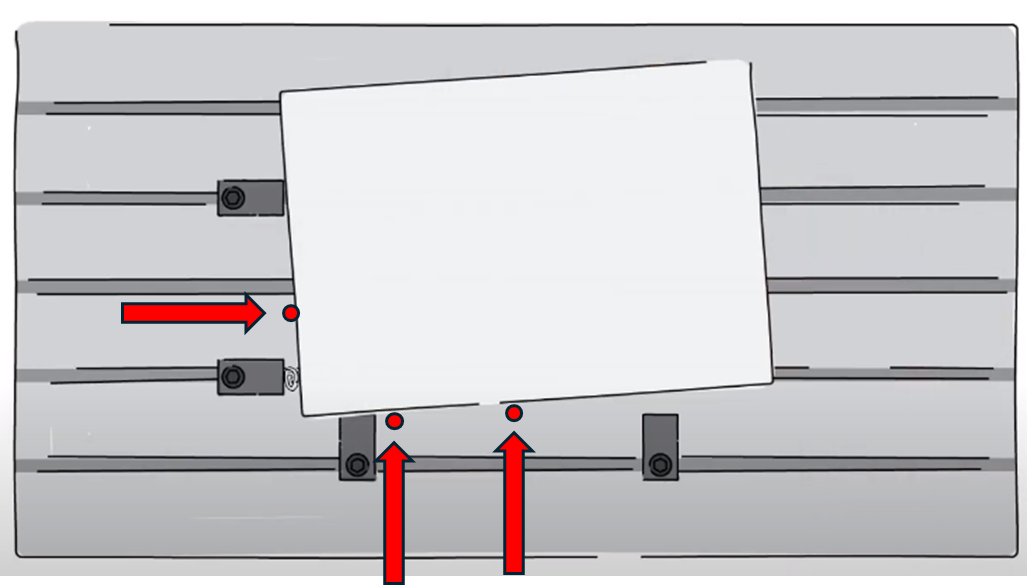

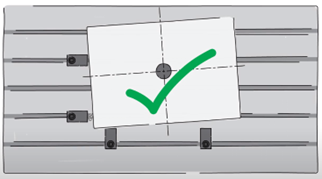

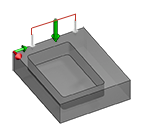

The part is probed to check for the position and orientation of the stock. |  The origin and orientation is corrected in the CNC controller. Another solution can be to move the part by rotating the plate. |  The controller compensates for the angular error and updates the machining coordinates to carry out the machining cycles at the right position and orientation. |

Types of Probing

The alignment of parts can be verified using three different strategies.

Side angle |  Top angle X |  Top angle Y |

Strategy Parameters

Dialog Area | Parameters | |

Parameters | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | ||

Approach and return in Z | Retract between touches | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Feedrate | |

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |

| |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||