Machine Tool Environment - MTE

Introduction

The Machine Tool Environment (MTE) is an optional software module designed to enhance the capabilities of Computer-Aided Manufacturing (CAM) systems. It functions as a comprehensive virtual machining environment, offering users the ability to simulate and optimize their machining processes before actual production begins.

Key Functionalities

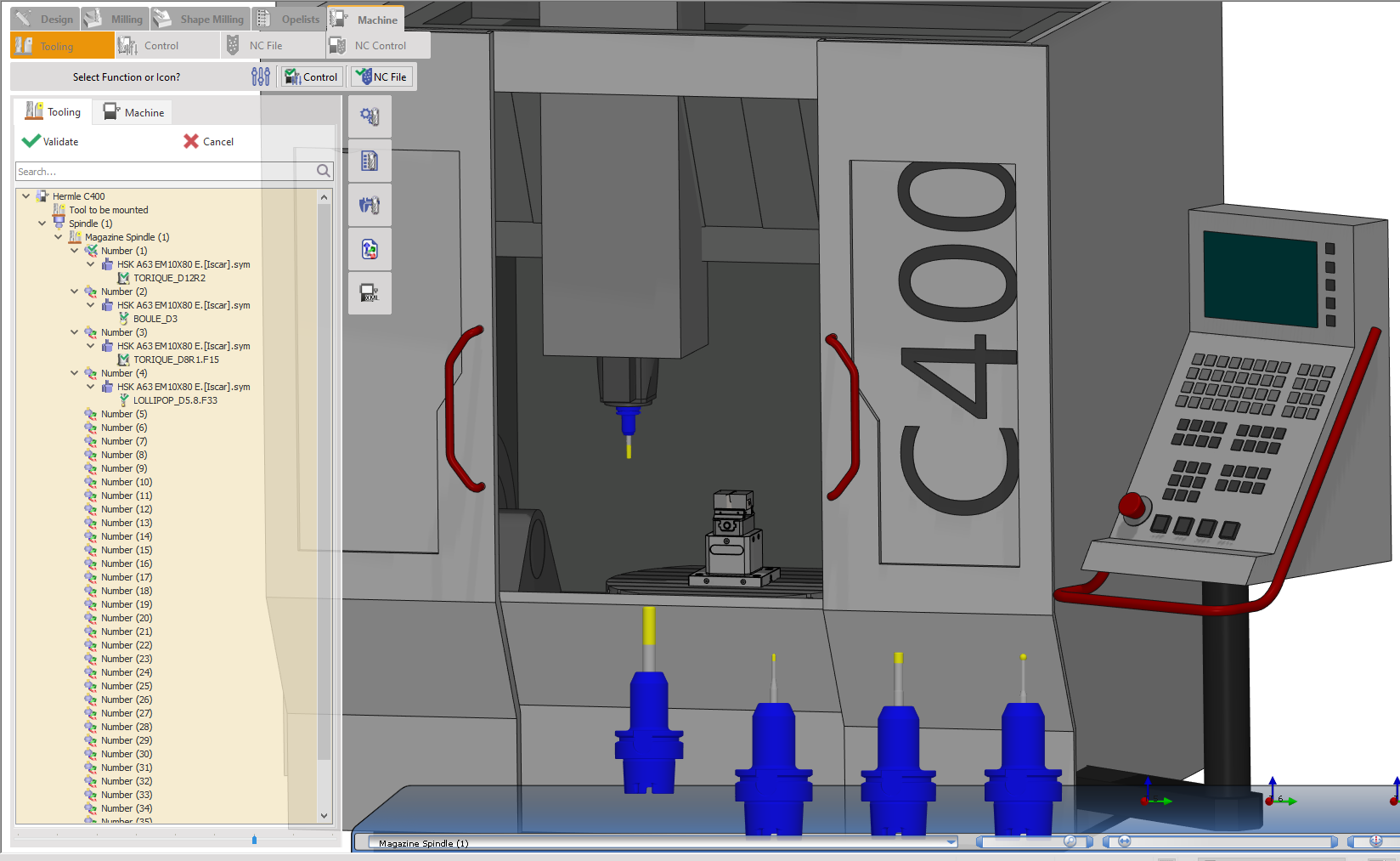

|  Example of MTE in Milling |

|

Principles

Post-Processor Dependence: Unlike conventional CAM simulations, MTE relies on a machine file with a loaded post-processor. This post-processor data provides crucial information about the inter-cycle movements and machine actions, enabling MTE to generate a highly accurate simulation.

Machine Kinematics Definition: MTE requires a pre-defined 3D CAD model of the specific machine tool used in the manufacturing process. This model, formatted in the X_T file format, accurately depicts the machine's kinematics (movements). Creating this model typically involves collaboration with a technician from GO2cam International or a reseller to ensure compatibility with the post-processor.

Machine Compatibility

MTE offers impressive compatibility across a vast array of machine tools, seamlessly integrating with most conventional machining setups. This versatility empowers users to leverage MTE's capabilities for a broad spectrum of manufacturing applications.

Activating the MTE module in your GO2cam license unlocks a new tab. This tab offers three dedicated menus for: |

|

|

%20-%20Introduction.png?inst-v=b44e98da-ee35-4dae-9eb1-dcda821d3f9a)