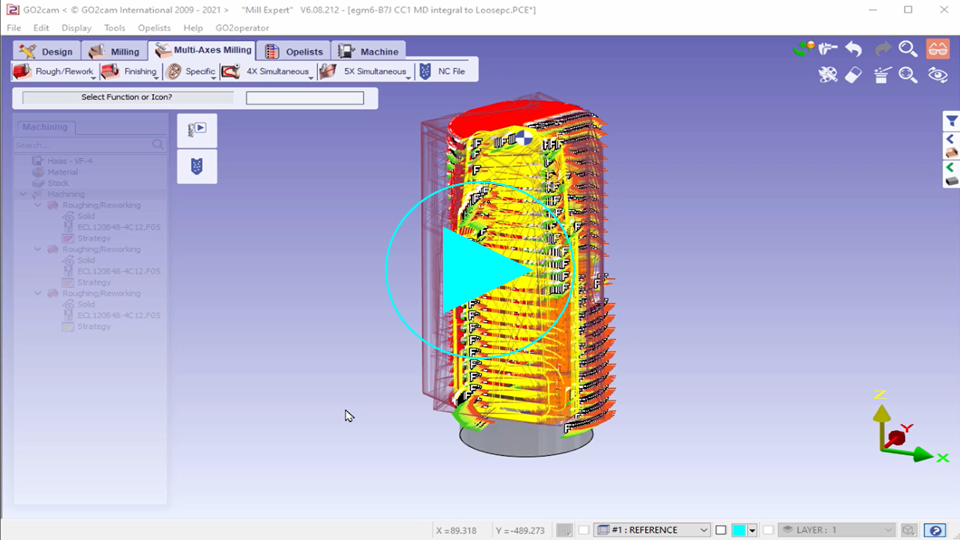

4X Facing Finishing

| Facing toolpath on 4 simultaneous axis. It involves using a cutting tool to remove material from a workpiece's face or surface while simultaneously moving along four axes of motion. |

Key Points

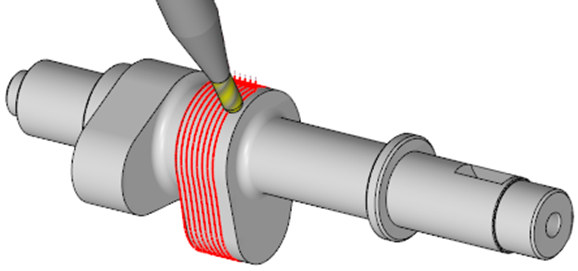

Avoid screw type parts! |  |

Strategy Parameters

Dialog Area | Parameters | |

Facing Strategy | ||

Inversion of path | ||

Limitation of Machining | Shift value | |

Starting Distance | Ending Distance | |

Stepover Calculation | Stepover (Tool ratio) | Stepover value (Ae) |

XY Scallop | ||

4 Axes Machining | Normal stock allowance | Tilt angle |

Tool safety clearance | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

XY Approach and Retract | Lead in length | Lead out length |

Lead in arc radius | Lead out arc radius | |

Leadin radius angle | Leadout radius angle | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |