End Facing

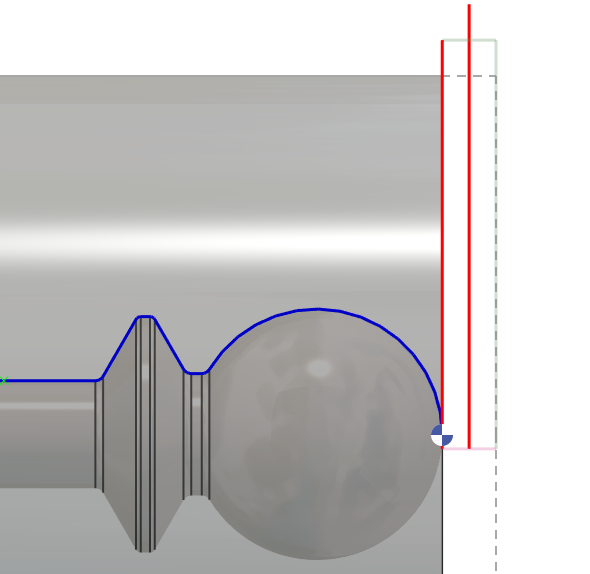

| This cycle allows the machining of a flat surface at the end of a cylindrical or rectangular workpiece. |

Key Points

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

R max Coef |

| |

Machining Strategy | Z Stock Allowance | |

Chip breaking | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Over cutting | ||

Facing | Limitate on Z axis | Exceed the axis |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Pass feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Users Fields | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||

Compensation achievement factor | ||