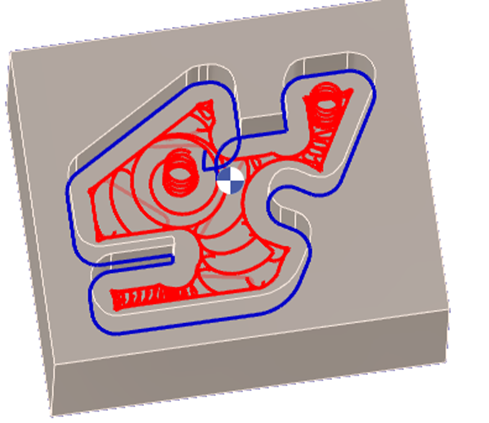

PAM - Rough Reworking

| PAM is a roughing toolpath which anticipates the finishing operation, with purpose to ensure a constant engagement angle in finishing. PAM is for Powerful Anticipative Manufacturing. |

|

Explore the advantages and patent information by clicking here. |

Key Points

The roughing PAM calculates a variable allowance all along the toolpath. Hence you can check that the tool engagement angle in finishing is always at a specific angle , in straight line and in any convex and concave corner! |  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | Maxi thickness(h) | Clearing area |

Type of clearing | Remaining thickness | |

Organization | Radii on contour | |

Preparing the finishing | Tool diameter | Remaining material |

Undercut and Reworking | Undercut machining | Island reworking |

Scallop reworking | Scallop value | |

Stock Calculation | ||

Limitation of Machining | Limitation Area | Mini machining area |

Stepover Calculation | Stepover (Tool ratio) | Stepover value(Ae) |

XY Scallop | Respect of scallop | |

Z Step (Ap) |  | |

Allowances | XY Stock allowance | Z Stock allowance |

Normal stock allowance | List of altitudes | |

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Approach and return in Z | Approach altitude | Retract altitude |

Return altitude | ||

Z Plunge | Plunge | Mini helix rad. |

Mini ramping rad. | Mini rad mach area | |

Plunge angle | ||

Management of rapids | Motions | Fmax safety distance |

Rapid/Fmax % | ||

Safety (in XY) | XY safety distance | SD/Tool shank |

Management of toolholder | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Rotation speed for plunge | ||

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |

| |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Toolpath Optimization | Rework Area Tolerance | Feedrate adjustment |

Curves Computing | Curve tolerance | Curve segmentation |

Toolpath Computing | Decomposition of arcs of toolpath | Arcs decomposition tolerance |